Forum Replies Created

-

AuthorPosts

-

Dan

Participant

Minor progress. Some sanding and beginning placement of #3 panels. More to come!

Dan

ParticipantHmm… I like this wet roll idea. I will definitely be trying that. Did you have any particular technique that worked well for you, or did you just drop your length of tape in a cup of epoxy and slosh it around?

Dan

ParticipantOk, now here’s where I ran into my first issue(s). My epoxy was setting way too quickly for me to do both side seams at the same time. That’s why there are no pics of my not-so-great filleting work. I got my thickened epoxy too runny at first and then over compensated and had to deal with it being too firm. That took some time but I decided to roll with it. I was running out of working time in the thickened epoxy but didn’t realize it until I had laid up both fillets (poorly). At this point I should have scraped both fillets and started over with a fresh batch of properly thickened epoxy and only done one side at a time.

Instead of being smart, I continued on by re-applying a thin brushing of un-thickened epoxy to both fillets and rolled out the correct amount of fiberglass tape on each side. By the time I got to saturating the second side, the tape had stuck well enough that I couldn’t adjust it without tearing out the fillet and I was left with this mess:

Welllll, that’s not good. So I fixed it the best way I could think of without starting over, which I’m not sure I could have done at this point anyway. I just cut the folds and smoothed them down. I won’t have a huge fold to sand down… just a little bump. I’ll just have to live with the tape on that side being a little off-center on the fillet.

I’m very pleased with the center seam. Very displeased with the sides. Overall, glad I get to move on to the next steps. Many lessons have been learned.

Dan

Participant

Dan

Participant

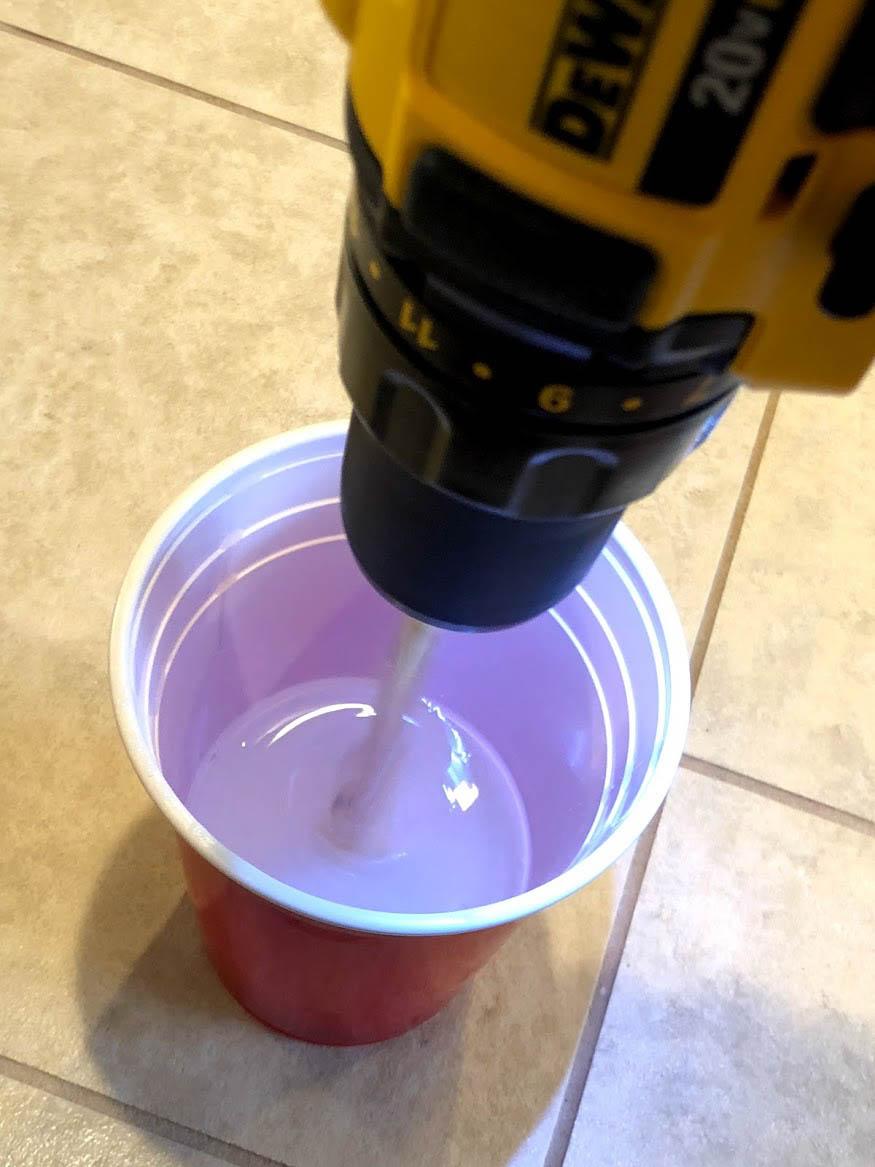

Made some filleting tools and a really fast stir-stick!

Dan

ParticipantBack to work on my teardrop!

Tack-welded the main panels together with ca-glue and removed the stitches along those seams.

Dan

ParticipantOutstanding! I’d planned to do exactly this in my build. I’m really glad you did it first. It looks great!

Dan

Participant

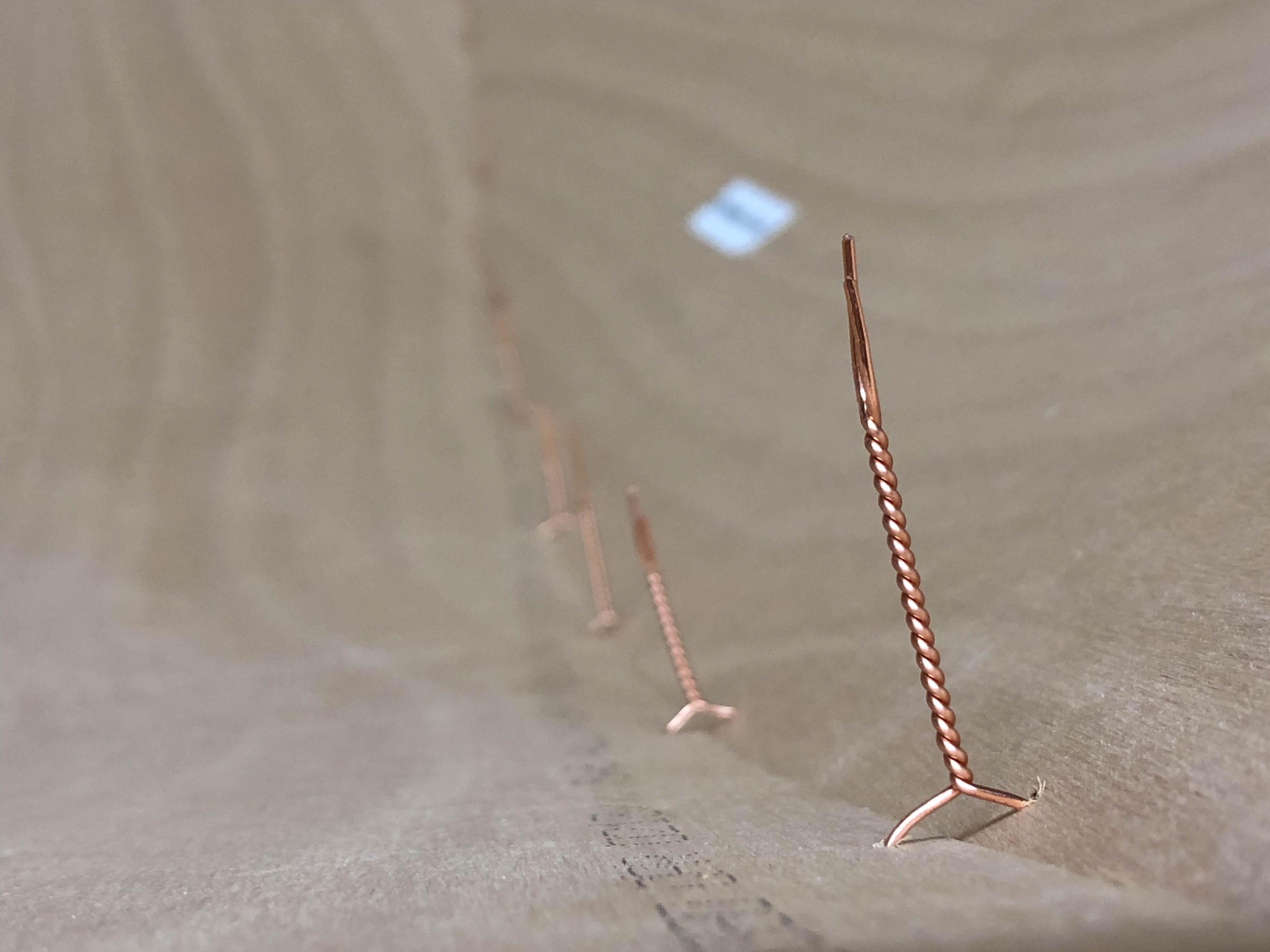

Robinson Wire Twister, inherited from my grandfather who built experimental aircraft. This tool is intended for twisting wire between drilled bolt heads to stop safety-critical bolts from unscrewing in harsh vibration environments such as aircraft (https://en.wikipedia.org/wiki/Safety_wire). It also works great for twisting the copper wire stitches as loosely or as tightly as needed.

Dan

ParticipantA forward/upward facing window is absolutely in the plan for my build… probably a non-opening window made of lexan and mounted the same as the door windows. Depends on structural integrity after removing the shell in that area. Stay tuned to my thread in the coming months for pics. 😉

-

This reply was modified 6 years, 4 months ago by

Dan.

Dan

Participant

My kitchen floor is warm enough for epoxy. I will, of course, need to get a heating solution for the garage for the next epoxy steps.

Dan

Participant

Too cold for epoxy, but screws still work! It’s going to be tight in here.

-

This reply was modified 6 years, 4 months ago by

-

AuthorPosts