Forum Replies Created

-

AuthorPosts

-

Dan

ParticipantGood choice on the trailer! I also went with the 12″ option after months of shopping around for something cheaper… but this one just works. Perfect size. High quality. Etc… A very real example of getting what you pay for.

Flip the axel inside the leaf springs. I did and everything fits perfectly. It also brings the teardrop down about 6″ to the correct height. You’ll be so much happier. I contacted the dude at Waterlust about their experience doing this with a much heavier setup and he said they’ve had no problems whatsoever.

Dan

ParticipantI’ve been doing other things for a while… but I’m back, baby! Prepare for many more photos…

At first I mounted the axel as instructed, but that made everything waaay too tall with the 12″ wheel option. So we ended up flipping the trailer over and re-mounting the axel inside the leaf springs instead of outside (same as Waterlust did).

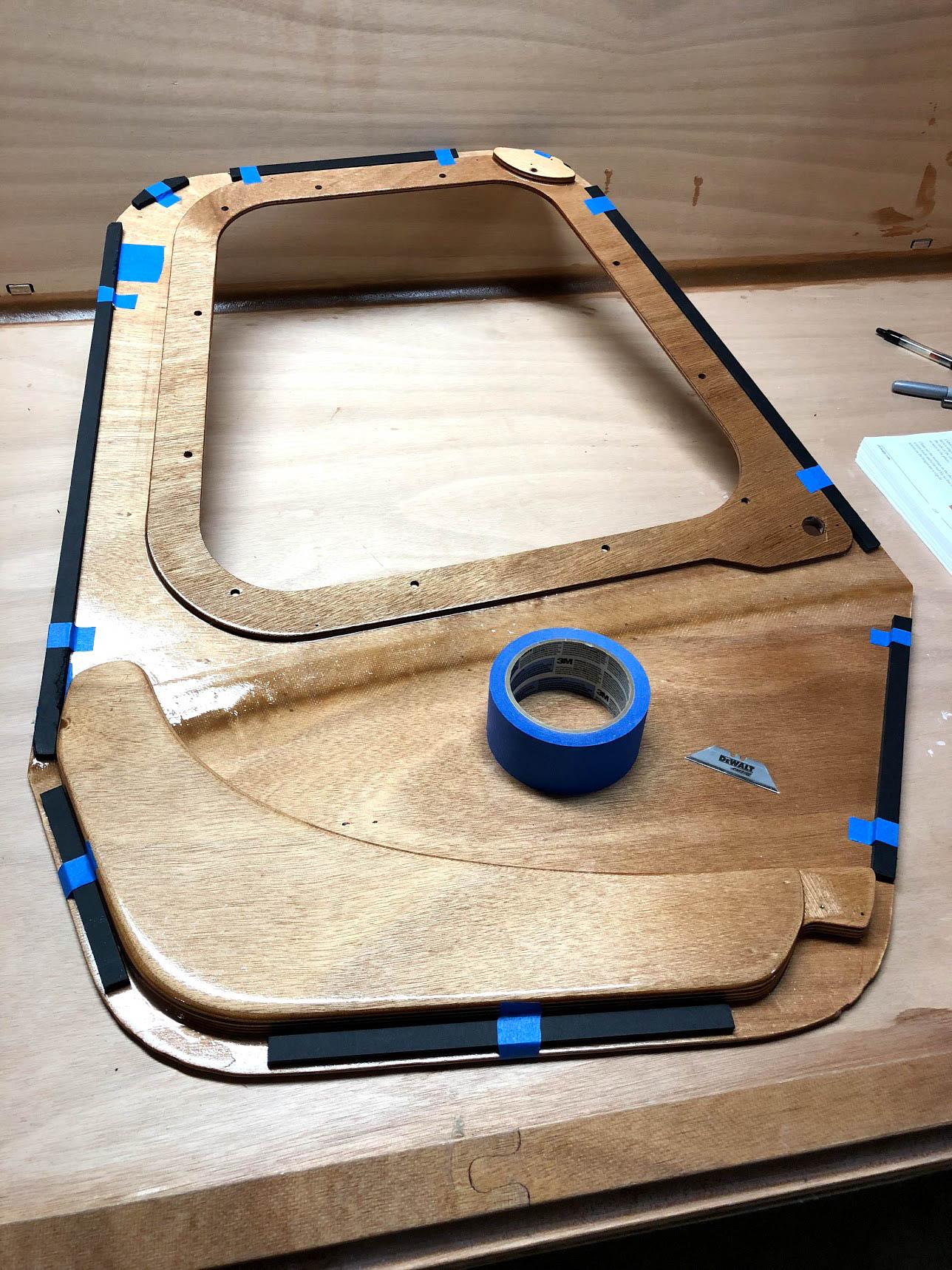

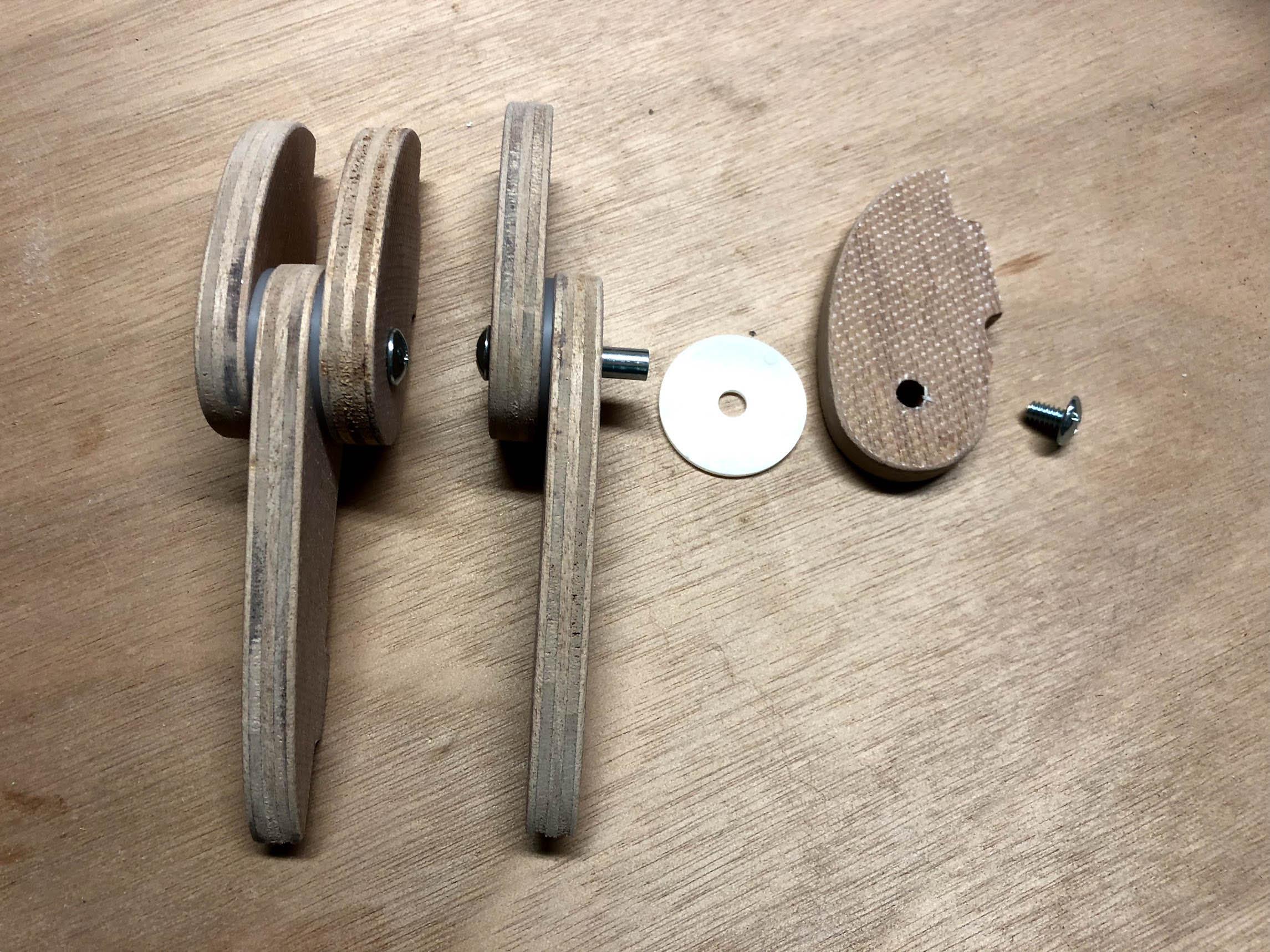

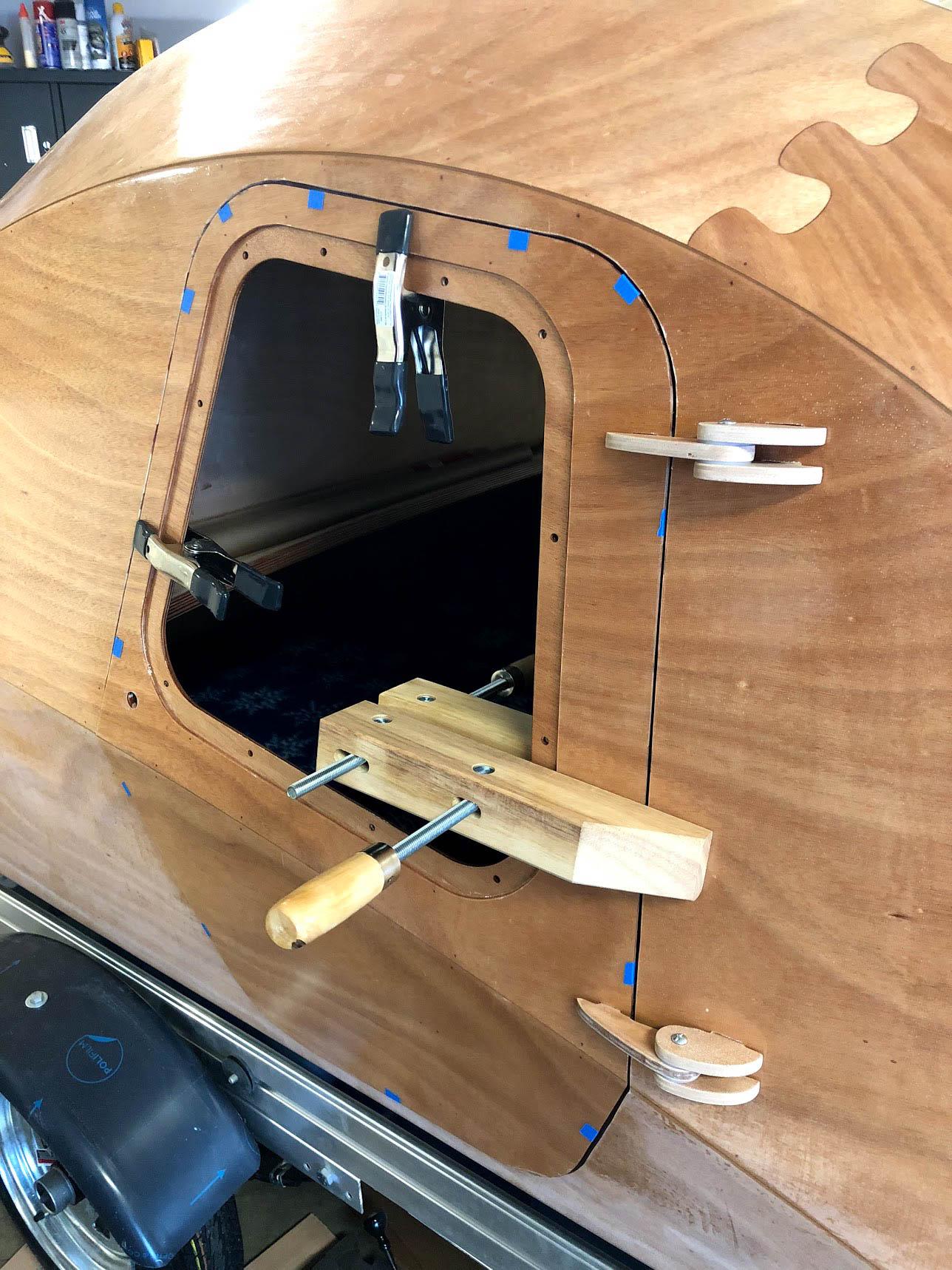

Got both doors mounted. I found that some foam-core board made an ideal spacer for getting the doors clamped down for hinge alignment. Then I went out and found some screw posts that happened to fit perfectly in my hinges once I added some nylon washers. Having replaceable bearing surfaces will be a good thing later, I’m guessing. I’ll try to find mylar or teflon washers and nice brass screw posts later. In the meantime, this hardware store junk should work great!

Next, it’s on to the galley hatch. I’ll also be adding nylon washers there. I’ve got a little file-work to do because that makes the hinges wider than the existing holes. To get things lined up, I stuffed the galley with pillows and stuff then squished the hatch down on top. I think this will work great!

I’m a little concerned about the width of the galley side-walls. I think I deformed them a bit in a previous clamping and filleting step. Now the opening is a little bit wider than the width of the actual hatch… oops. We’ll see how things look later this week after I finish the hinges.

June 21, 2018 at 4:03 am in reply to: Should I try to remove epoxy from door cut lines prior to fiberglass sheathing #1910

June 21, 2018 at 4:03 am in reply to: Should I try to remove epoxy from door cut lines prior to fiberglass sheathing #1910Dan

ParticipantI also had no issues cutting through the epoxy. Most of my lines were filled with epoxy because I backed them with tape before doing the exterior fiberglass job. I didn’t want runs inside.

I had other issues when it came to cutting the rounded door corners. I think the bansai saw I got wasn’t very good… too few teeth per inch meant the cut was too aggressive and I had a hard time following the curve.

-

This reply was modified 5 years, 10 months ago by

Dan.

Dan

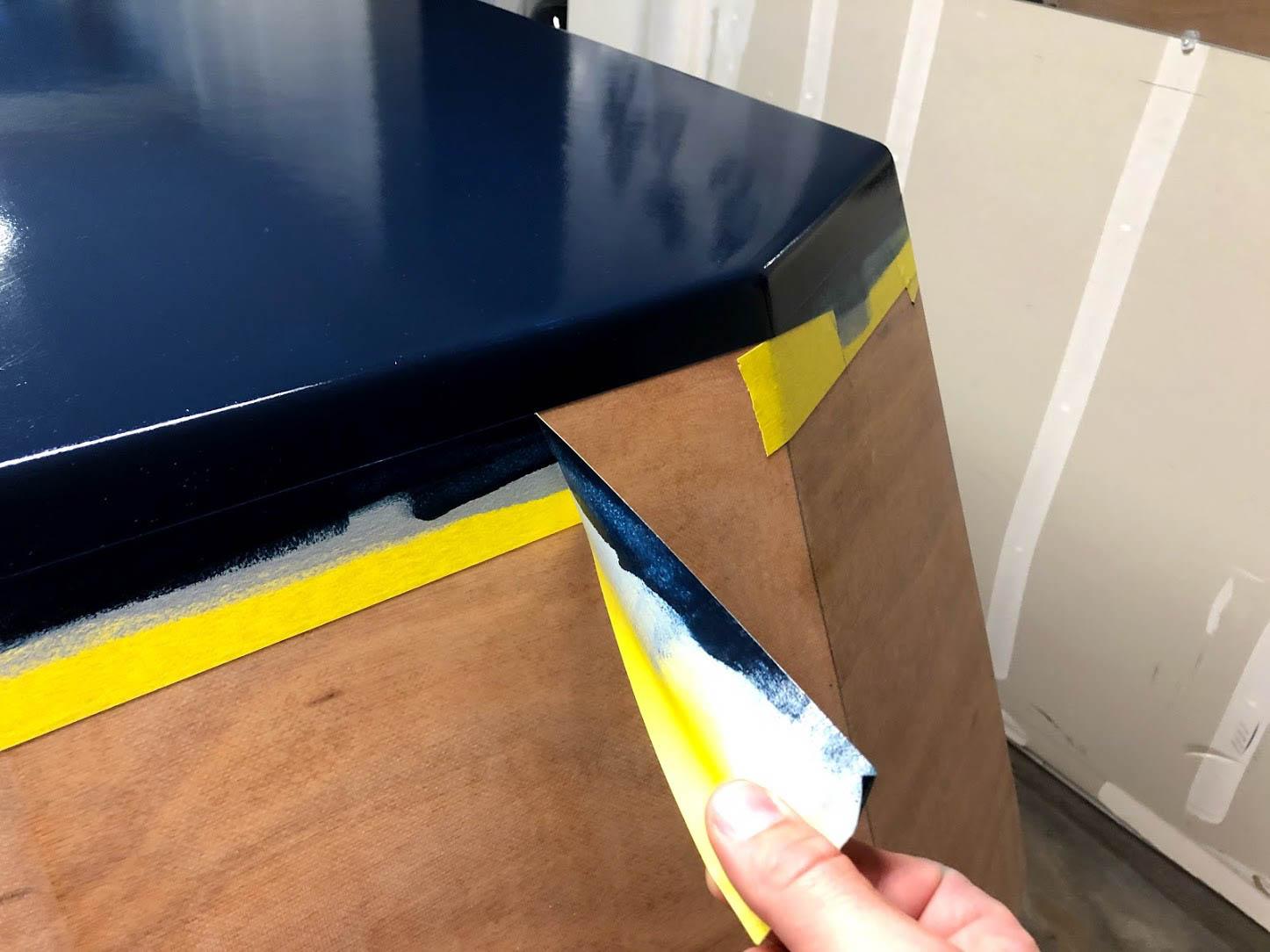

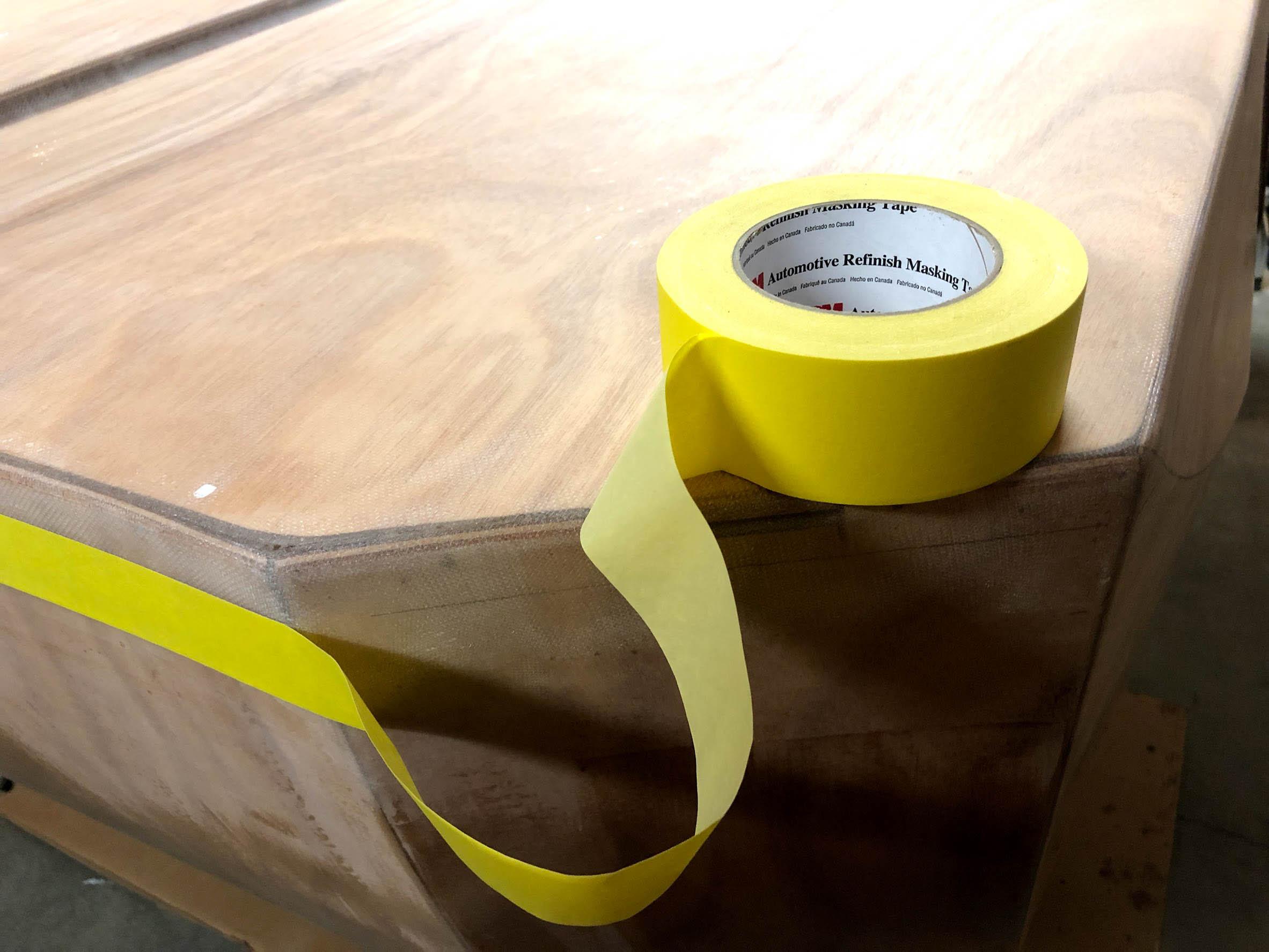

ParticipantGot three coats of paint on the bottom. It’s not perfect, but it’s way better than just good enough… except for that sexy masking line, which IS perfect all the way around. I can now highly recommend 3M Automotive Refinish Masking tape, procured from my local auto-parts store. After being in place for a week and getting multiple coats of paint, it created a super sharp line and left behind zero residue.

I’ll apply a coat of wax to the painted surface just before flipping it onto the trailer next weekend. Hopefully the paint is cured enough by then. I’ll add some pin-striping later, after installing the eyebrows but before varnish. In the meantime, while the paint is curing, I’ll be working on the doors and galley hatch. I got a coat of epoxy on the doors yesterday.

You can see the huge difference in those fillets on the doors. Those were the first “flat” fillets I did. So sloppy.

-

This reply was modified 5 years, 10 months ago by

Dan.

Dan

Participant

Primer last night. Paint tonight. I sure hope this tape leaves a clean line…

Dan

ParticipantHmm. I just realized I could have taken the bearing off my 1/2” round over bit, as @rovineye did, and clamped a straight-edge in place to guide the router. Oh well.

Bubbles have been filled. Bottom and transom are sanded and ready for paint, which arrived today. I just need to wipe everything down and mask it off. So close to flipping it back over!

Sanded for at least 4 hours on Saturday. They say wooden boat building is 90% sanding. It appears the same is true for teardrops…

Dan

Participant@abrightwell, Thanks for the paint info! I ordered the same paint (I also love that color) along with primer and thinner from TotalBoat. I’ll only be painting the bottom, like CLC did on their show model. Might do a little pinstripe work as well. The paint should arrive this week just after my extra epoxy comes from CLC. In the meantime, I have done a fill-coat on the bottom and nothing else. Next up is filling those bubbles, then onto sanding sanding sanding, followed by paint, then flip and mount… then on to some fun finishing work!

Dan

ParticipantI’ve have a pack of syringes coming from CLC with my extra epoxy. I’ll do some filling… probably. I’m sooo eager to get this thing turned back over and mounted on the trailer. Hopefully I can get a fill-coat and some paint on it by this weekend.

Need to figure out what paint I want to use and what color… probably just black.

Dan

ParticipantGot everything cleaned up, filled in, and ready for glassing. Couldn’t get the 1/2″ radius on the butt block like I wanted because the router bit I have hangs down too far. I only was able to get the 3/8″ bit to fit in the space I had.

Pro Tip: round-over the butt-block before installing it. You will have a much easier time if you do that. The manual should mention this… and I should have thought ahead and done it even without the instruction. Even better would be to rip-cut the edge at a 45-degree angle and then sand down. You wouldn’t even need a fillet if you did that.

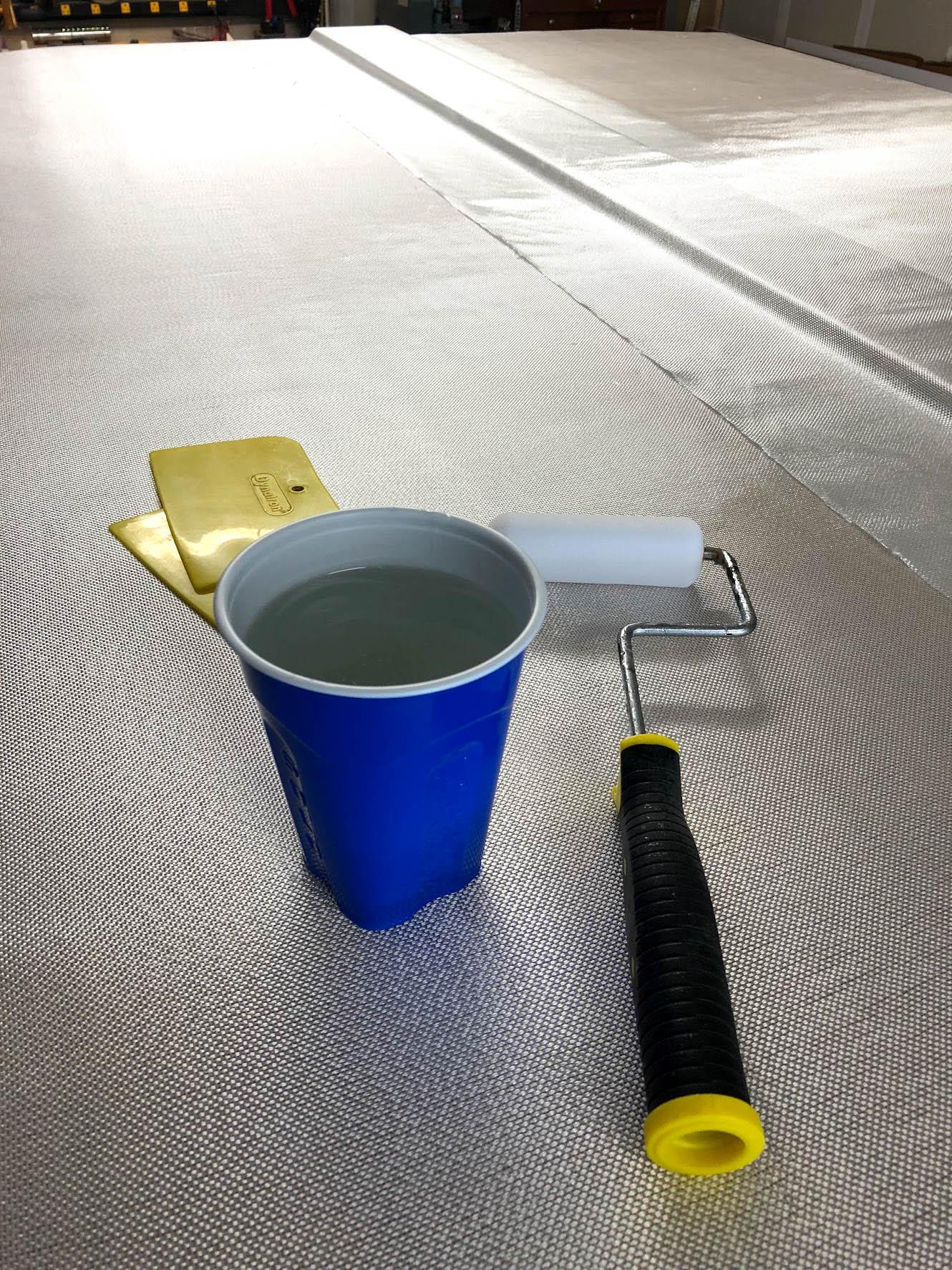

While I was filleting things, I also finished the cabin shelf fillet and glass. This is a good example of pre-wetting the fiberglass before application.

On to the last big fiberglass job. Lots of lessons to re-learn coming up in … 3 … 2 … 1 …

Ok… first lesson learned. I should have absolutely NOT done both sides at the same time. I have neither the experience or innate skill to do a quality job of it. It’s OK, but not half as good as it should be. I tried soooo hard to keep bubbles from forming at the butt block but I just couldn’t get them all out. With the two layers of cloth and insufficient radius on the block itself, I was doomed to failure. It would have been possible, I believe, if I had only one layer of cloth. Or a better radius.

Pro Tip: Do one side. Let it cure for a few hours. Then do the other side. Especially if your butt-block isn’t as rounded as it should be.

Second lesson is to keep the cut edge of your cloth near the butt-block, as they show in the manual, not overhanging the side like I did. If you have it overhanging like me, forget about the tape. The cut edge loves to fray and come apart (as you know) and removing the tape from under the saturated cloth makes a sticky, stringy nightmare you’ll be chasing with scissors. You need the reinforced edge of the cloth down there to keep it all together.

Man, I’m glad this step is done. I’m going to give the bottom a second coat of epoxy an then probably paint.

Also, I’m basically out of epoxy (I have been making over-sized fillets for everything). I was afraid I would run out while doing the bottom glass but I went ahead anyway. My last jugs of resin and hardener are alarmingly light. I ordered another gallon of resin and half-gallon of hardener so I’ll have enough to finish the interior and the galley.

Dan

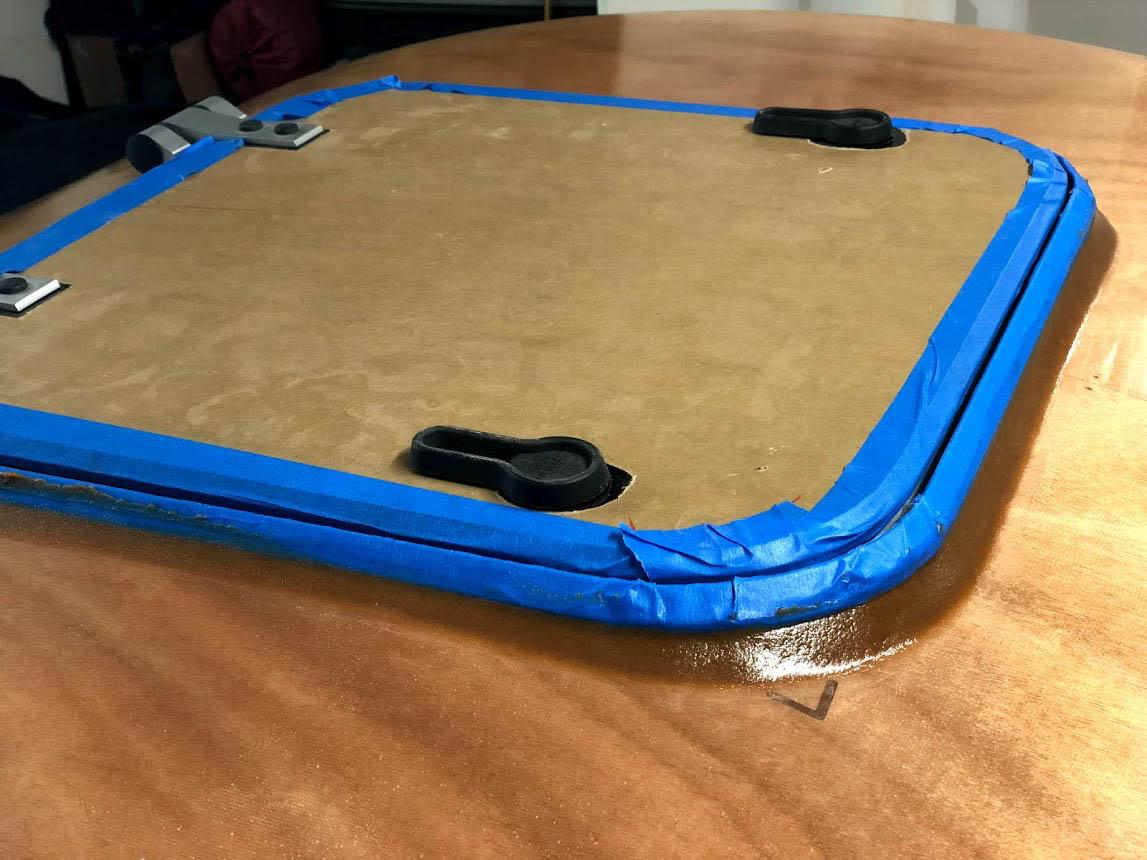

ParticipantIn doing my non-standard top hatch, I learned that a bit of an epoxy fillet will fill the gap nicely if you want to mount on a curved surface. If you want your part to release after the fillet cures then you can carefully cover it in packing tape, which the epoxy won’t stick to. Just be careful to make sure the part will be able to pull straight out without getting caught on anything. My hatch has an extruded aluminum frame which was bent into shape at the factory. The bending caused the corners to flare out very very very slightly. This was enough to lock it in place when the fillet cured around it. I had to do some careful hammering to knock it out. If I was to do it again, I would probably buy a pack of big Post-it notes to cover the surface with a couple layers of paper (for spacing and easy removal) and THEN a layer of packing tape.

Good luck!

Dan

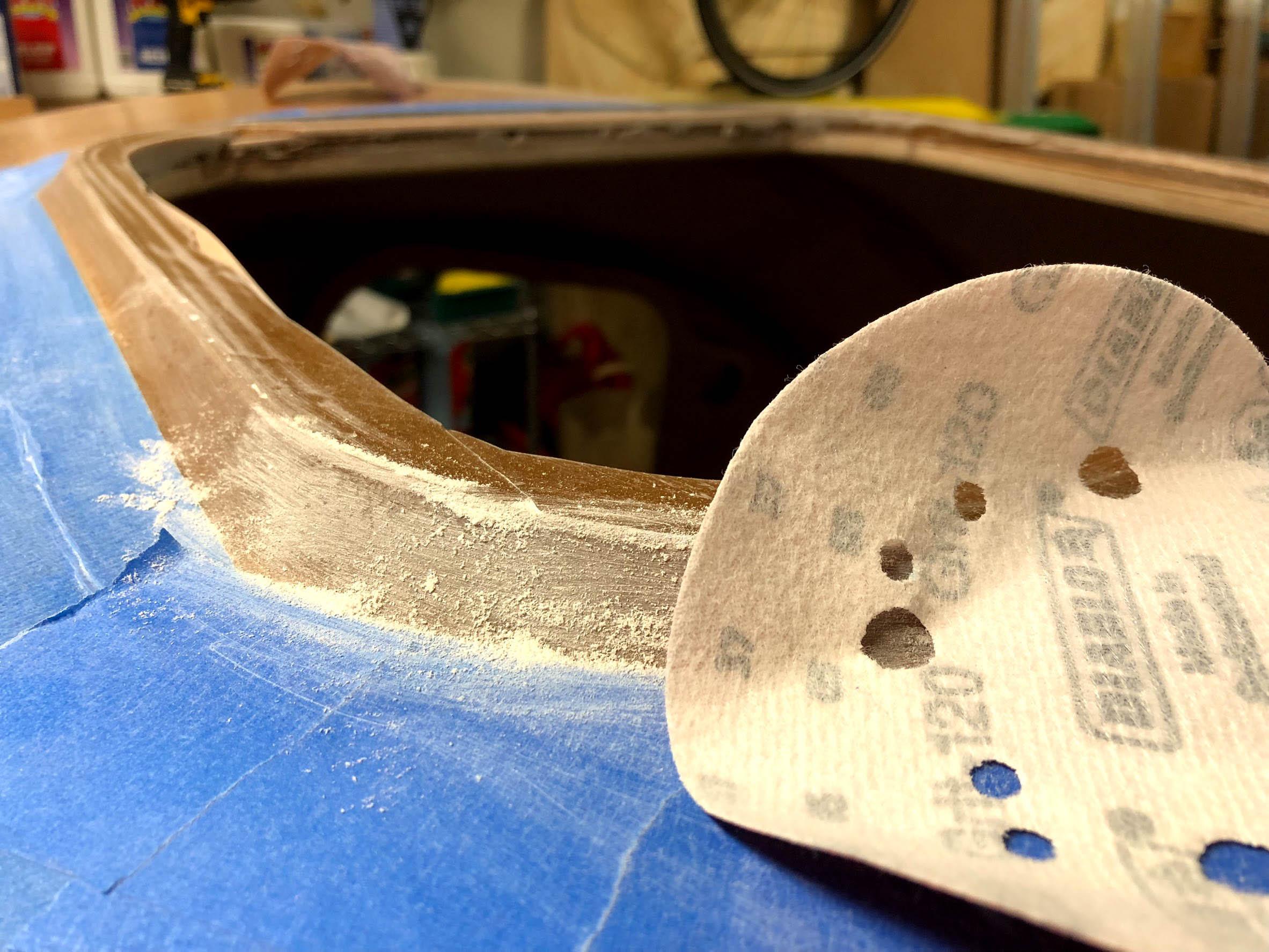

ParticipantI did a bunch of cleanup on the top hatch fillet. I both sanded and polished the exterior of the fillet and filled voids where thickened epoxy hadn’t fully squeezed in. The fillet will get a coat of un-thickened epoxy and then varnish along with the rest of the shell when I do the final finish. I added cel-o-fill along with the wood flour when I was thickening the epoxy for this fillet, so it is somewhat lighter in color than all the other fillets and hopefully will blend with the color of the shell a little better in the end.

Then I wet-sanded the rough edge of the hatch lens up to 600-grit and finished it with polishing compound to get it optically clear. I am very pleased with the result of that.

After that was done, I couldn’t take it anymore and removed the protective film from the hatch. Behold:

Pictures can’t really do it justice. I somehow got everything square and even and shiny. I am sooo happy with the result! So now the hatch now goes back in its box while I finish things up. It will eventually be bedded with butyl caulk and carefully screwed down.

Next, I installed the transom panel. No need for copper stitching… I just held things in place and tacked with CA glue. Then gaps got covered with masking tape to prevent epoxy squeeze-out.

Nearing the end of the project… I’m finally getting decent at fillets.

Next we got the whole thing flipped over for bottom finishing. That top hatch fillet and frame is very strong!

A little 60-grit sanding and gap filling to do then we’ll be ready for glass.

Dan

ParticipantOk, this was the big weekend. I finally pulled the trigger on my top hatch! It went pretty smoothly overall. First I epoxied in the frame to get everything held in the correct shape. After that epoxy cured enough I was able to do the hatch itself. Here’s the frame getting ready to be clamped. This wasn’t enough thickened epoxy. I had to make another batch to finish the fillet.

Here it is the next day with the hatch removed. Those two clamps squished the top of the shell down just a bit and the cured epoxy is holding it in that shape. Now to fill in the gaps then set the hatch in place and fillet it.

Then wait an hour and do some smoothing with denatured alcohol.

And here’s one of the main reasons I wanted this kind of hatch… it’s looooow profile!

Some hours later and after some careful hammering, I got the hatch out to remove the protective tape. Now I just need to clean up that mondo fillet and I’m calling the top hatch pretty much done. I’ll bed it with butyl caulk and screws.

-

This reply was modified 5 years, 11 months ago by

Dan.

Dan

Participant@ArtisticAdam mentioned that he figured that out here. Maybe he can share his video with you.

Dan

ParticipantGot the starboard doorframe epoxied in last night. Top hatch this weekend.

Dan

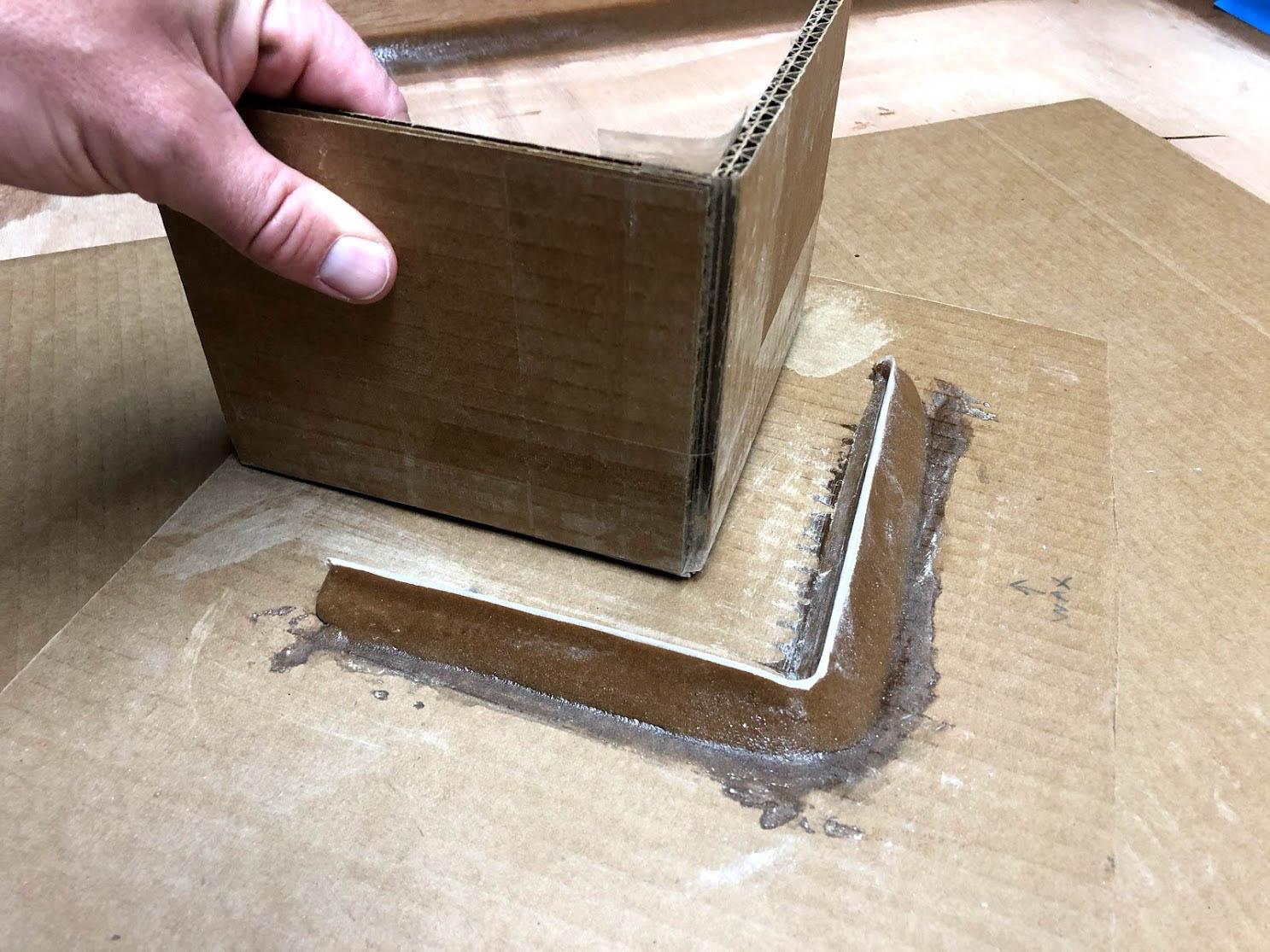

ParticipantOk, I’ve got the top hatch inside bezel just about how I want it and I figured out that I can just fillet around the exterior bits. Packing tape turns out to be an excellent mold release to keep the epoxy from sticking to stuff. I made a test article out of cardboard and packing tape which released from the epoxy fillet super easily. With that knowledge I taped up my hatch and will probably finish installing it this week!

My only other progress is installing the cabin shelf and getting the starboard side door frame prepped.

-

This reply was modified 5 years, 10 months ago by

-

AuthorPosts