Forum Replies Created

-

AuthorPosts

-

restonthewind

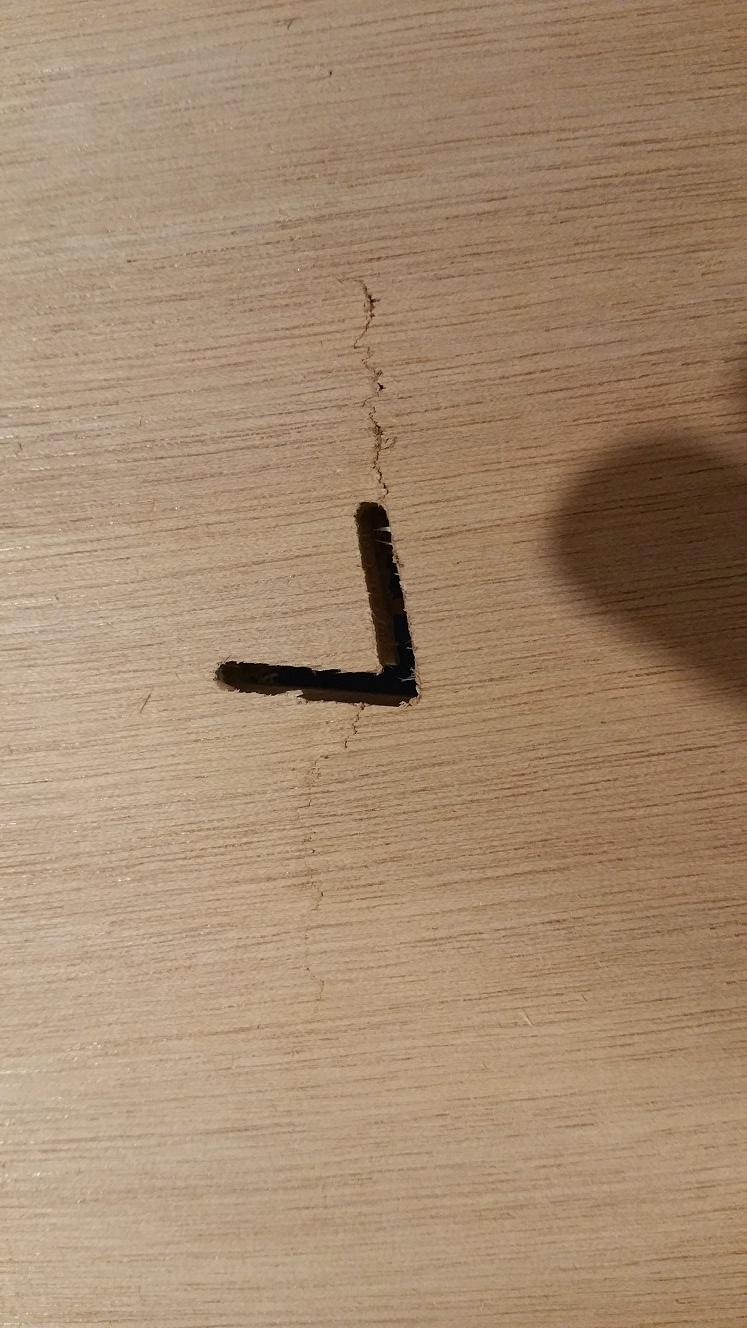

ParticipantThe same panel also fractured at the roof hatch. This fracture occurred earlier when I wasn’t doing anything unorthodox, though I’m not sure I was fitting the panel into the mold properly. I heard the fracture and later saw a slight discontinuity in the shade of the surface at the roof hatch on the inside, but I wasn’t sure what had happened, and the fracture wasn’t apparent from the inside. After the larger fracture occurred, I removed the panels and inspected the roof hatch fracture more closely.

-

This reply was modified 6 years, 11 months ago by

restonthewind.

restonthewind

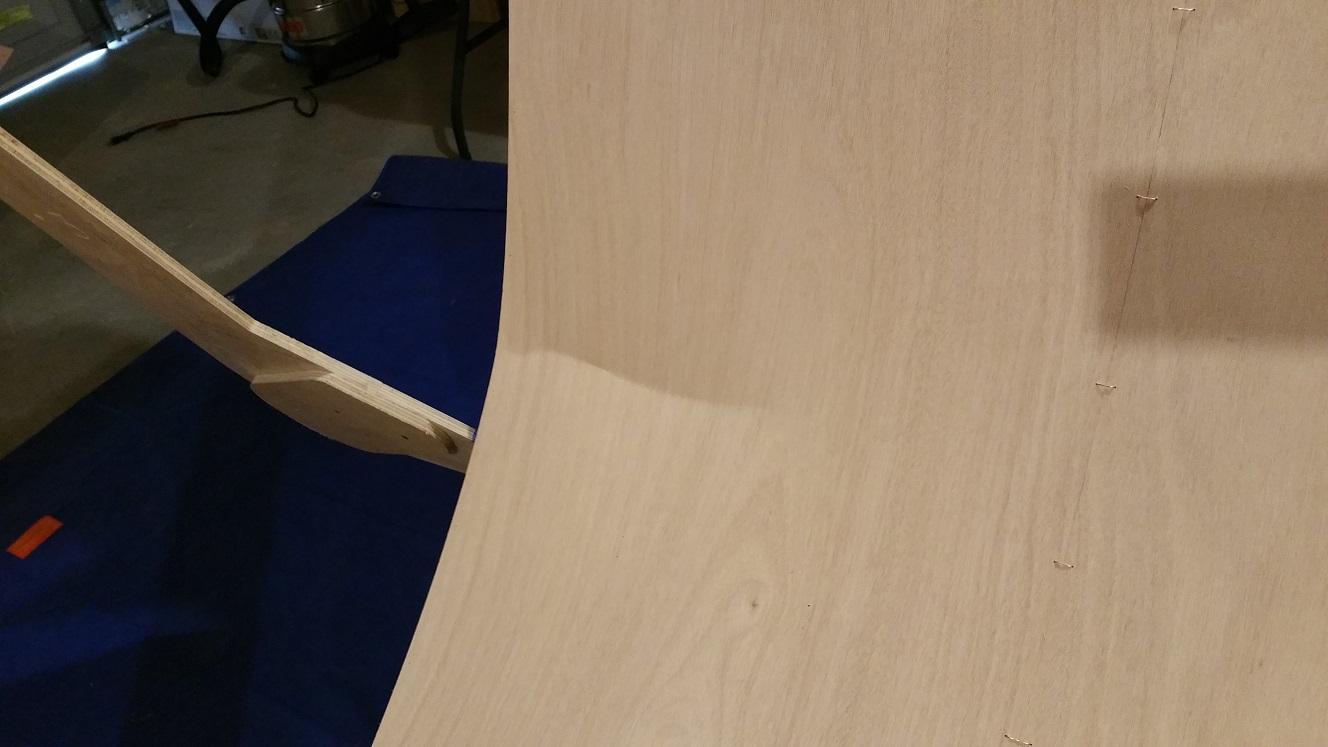

ParticipantWhile fitting the top panels into the mold, one of the panels fractured.

I was applying light pressure to the panel from behind mold frame 1 while my wife pushed from the other end to work the panel into the mold when the panel fractured, so I may be responsible for the damage. Regardless, I don’t believe I can continue with this part, so I’ve asked CLC to replace one or both top panels (two or four parts). Ed may recommend a repair with fiberglass tape instead, but I wouldn’t attempt one without advice from CLC. Ed Whigglesworth is managing my account and has been very helpful.

The panel with the more successful fiberglass taping job fractured, so if replacing both panels is not much more costly than replacing one, I’ll replace both. I’ll log the cost of these mishaps as they occur. It’s Sunday, so I don’t expect a reply today. Hopefully, my replacement bulkhead hasn’t shipped yet.

I didn’t much expect to reach the end of project without replacing a part, but I hoped it wouldn’t happen so soon. Hopefully, I’ll be back in business before next weekend. I’m traveling the following weekend and will be away from the house for two weeks.

-

This reply was modified 6 years, 11 months ago by

restonthewind.

restonthewind

ParticipantThe second mistake occurred while joining parts of the top and side panels with fiberglass tape and epoxy.

The first three joins look good, but by the time I reached the fourth, the epoxy was thickening. I didn’t notice the heat until too late. Some of the tape was covered with thickened epoxy, and even after mixing a new batch, I couldn’t saturate it.

I applied too much epoxy and still couldn’t saturate some of the tape. I’m still waiting for the epoxy to cure. After sanding in a few hours, I may remove unsaturated tape with the sander and add a patch, but I’m inclined to live with it. Most of the tape is saturated. Insulation will cover this joint on the interior, and the exterior fiberglass will hold the parts together eventually, so some weakness in the bond seems tolerable.

I wasted quite a bit of epoxy and a length of fiberglass tape on this exercise but learned to be more attentive to the consistency of the epoxy. The temperature in my garage is already in the high eighties in the afternoon and will reach the nineties soon, so I’ve moved the unmixed resin and hardner inside. It will be around 70 degs before mixing, and I’ll confine my epoxy work to the early morning and late evening.

-

This reply was modified 6 years, 11 months ago by

restonthewind.

restonthewind

ParticipantMy first mistake occurred while building the frame.

I read the manual first, honestly, but by the time I glued and screwed the butt blocks to mold frame 3, I had forgotten the warning on p. 24, so I had to cut away part of two butt blocks.

The mishap provided my first experience with a Japanese handsaw. The cut on the other butt block is cleaner. On the second attempt, I seemed to be sawing into the mold frame, so I started over. the cut in the butt block is beveled, and I restored a smooth surface to the mold with the sander.

restonthewind

ParticipantAs luck would have it, my kit arrived with a bulkhead damaged in transit.

The damage presumably occurred in transit, because the box was damaged on one side and the material gouged from the bulkhead was also in the box.

I possibly could have used the damaged bulkhead, because I’ll remove the damaged portion anyway, but CLC is providing a new part. The upside for me is a second bulkhead for experimentation. I have practically no woodworking experience and no experience with a circular saw or saber saw. If the damaged bulkhead seems too flimsy after cutting the hole from it, I’ll reconsider the whole idea (no pun intended).

restonthewind

ParticipantThanks for sharing your misfortune. It has convinced me not to build the removable galley flat, attached with lift off hinges, described in my thread. I’ll use the wood to build a small table or two instead.

restonthewind

ParticipantMy kit arrives today, so I’ve cleared out my garage and am taking inventory. The builder’s manual claims to use “inexpensive 2-inch spring clamps throughout”. I have 60 of these clamps, but your clamps appear longer than two inches, and clamps on the door in the manual appear longer. I won’t need them for a while, but I wonder. Will the two inch clamps really suffice?

restonthewind

ParticipantFeel free to hijack. How are you inside of the shell at this point? Have you not installed the floor?

restonthewind

ParticipantThe doors and hatch seem the most error prone, and people have posted about ill-fitting doors, so let us know how your approach works. Installing the sill and stiffener through the window before cutting the door seems tricky too.

restonthewind

ParticipantHere’s the plan after reading the builder’s manual last week. I avoid changes to the build procedure as much as possible. My kit ships on May 30th, and I’ll start on June 3rd at the earliest. I’ll decide definitely whether to make these changes when I reach Chapter 5. I hope to finish the shell, end of Chapter 6, by the end of June. July will be hot in Georgia. I’ll post pictures if and when I actually modify parts.

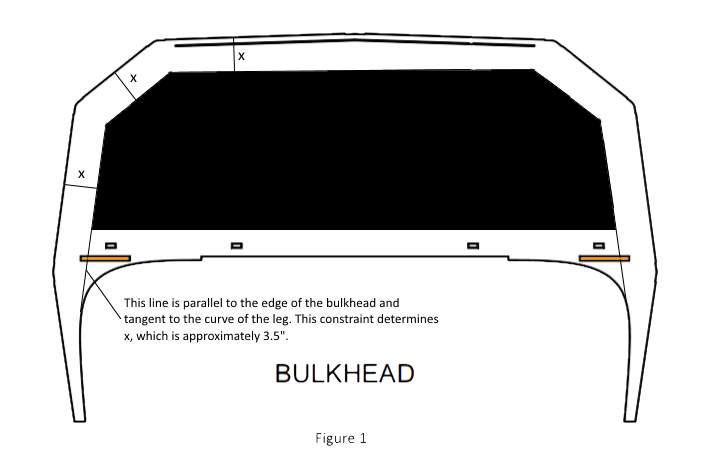

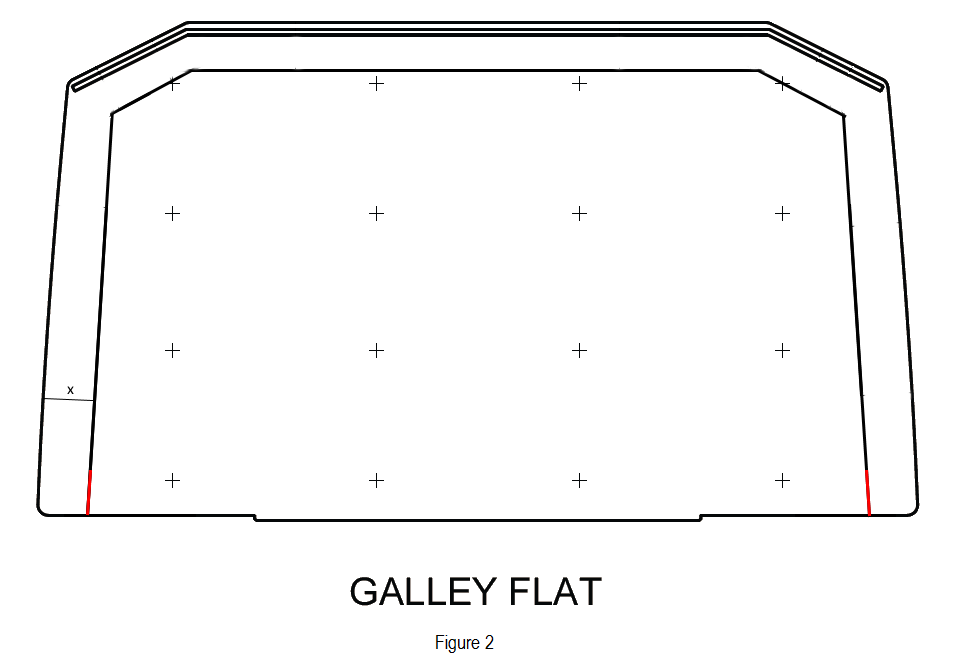

1. Before fitting the bulkhead and galley flat (Chapter 5), modify these parts as follows.

A. Cut a hole in the bulkhead as indicated in Figure 1, and mark the bulkhead with the indicated lines. Fill the slots for the galley flat with wood putty and sand after curing.

B. Cut from the galley flat the parts fitting the slots filled in the bulkhead.

C. Mark the galley flat with the line indicated in Figure 2 and cut the portions of the line in red. Secure a thin piece of something into the cut to prevent pressure on the side of the flat closing it.

2. Modify instructions in Chapter 5 as follows.

A. On p. 87, omit the stiffeners.

B. On p. 92, apply no glue to the bulkhead slots. Wood putty fills the slots.

C. On p. 93, apply no glue to the mating edge of the bulkhead.

D. After dropping the flat in place on p. 93, drill holes and stitch the flat to the bulkhead along the mating edge.

E. On p. 94, apply the epoxy fillet between the flat and bulkhead only up to the red line cut in 1.C.

F. On p. 98, do not round the edges of the bulkhead and flat.

G. On p. 99, do not epoxy the surface of the flat within the line marked in 1.C.

3. After cutting the hatch, at the end of Chapter 7 or anytime thereafter, remove portions of the bulkhead and galley flat.

A. Remove the stitches applied in 2.D.

B. Supporting the galley flat from beneath, cut it along the line marked in 1.C. Remove the portion within the line.

C. Cut the bulkhead along the lines marked in 1.A. Remove the portion between the lines.

D. Sand and epoxy the cut edges.

4. The portion of the galley flat removed can be replaceable, restoring some horizontal rigidity.

A. Remove the portion of the flat fitting the mating edge of the bulkhead.

B. Shorten the stiffeners and glue them to the removable flat.

C. Sand and epoxy the removable flat.

D. Attach lift off hinges to one side of the top of the removable flat and flat border and a latch to the other side.

E. Since the bulkhead does not support the flat, attach an adjustable table leg to the center of the bottom.

What can go wrong?

Removing so much of the bulkhead and galley flat reduces the rigidity of the shell. The walls could buckle, particularly with load on the roof. Installing the removable flat addresses this concern, but if the walls buckle much with the flat removed, the latch may not close.

Solution: Attach a kevlar line with a turnbuckle between the bulkhead borders just above the flat. The line adds horizontal rigidity, and the turnbuckle can correct for a little buckling when installing the flat. With the flat installed, the line is also a fiddle. Without the flat installed, it’s a clothesline or something, and it’s easily removed. With no load on the roof, the support seems unnecessary. A second line further up the bulkhead adds more rigidity and is better positioned for hanging things.

restonthewind

Participant>Instead of mushroom vents, I installed clam shell vents.

The black mushroom vents look nice, but I plan to follow your lead.

-

This reply was modified 6 years, 12 months ago by

restonthewind.

restonthewind

ParticipantWithout the galley bulkhead and flat, raising the galley hatch creates a lot of interior space in the rear of the camper, and soft walls (tent fabric) enclose this space. In warm weather, opening the hatch creates a large, well-ventilated space. In cold weather, closing the hatch creates a smaller, well-insulated space requiring less energy to heat. With the soft walls removed and the removable flat in place, the hatch still works as designed.

restonthewind

ParticipantRegarding axle flipping (above), the video at Northern Tools’ website shows the axle clearly at 30 seconds. The axle is “flipped” in its normal orientation, so the trailer can’t be raised this way.

restonthewind

ParticipantCorrection: The width of the bulkhead above is more like 2.5 inches, seems too little wood.

restonthewind

ParticipantThanks, SOMDTD. I don’t worry much about the towing speed with 12″ tires, and I see your point about the galley height. Now that you mention it, getting the roof above my head would raise the galley flat nearly to my shoulders, so this myth is busted.

-

This reply was modified 6 years, 11 months ago by

-

AuthorPosts