Forum Replies Created

-

AuthorPosts

-

canadianhoser

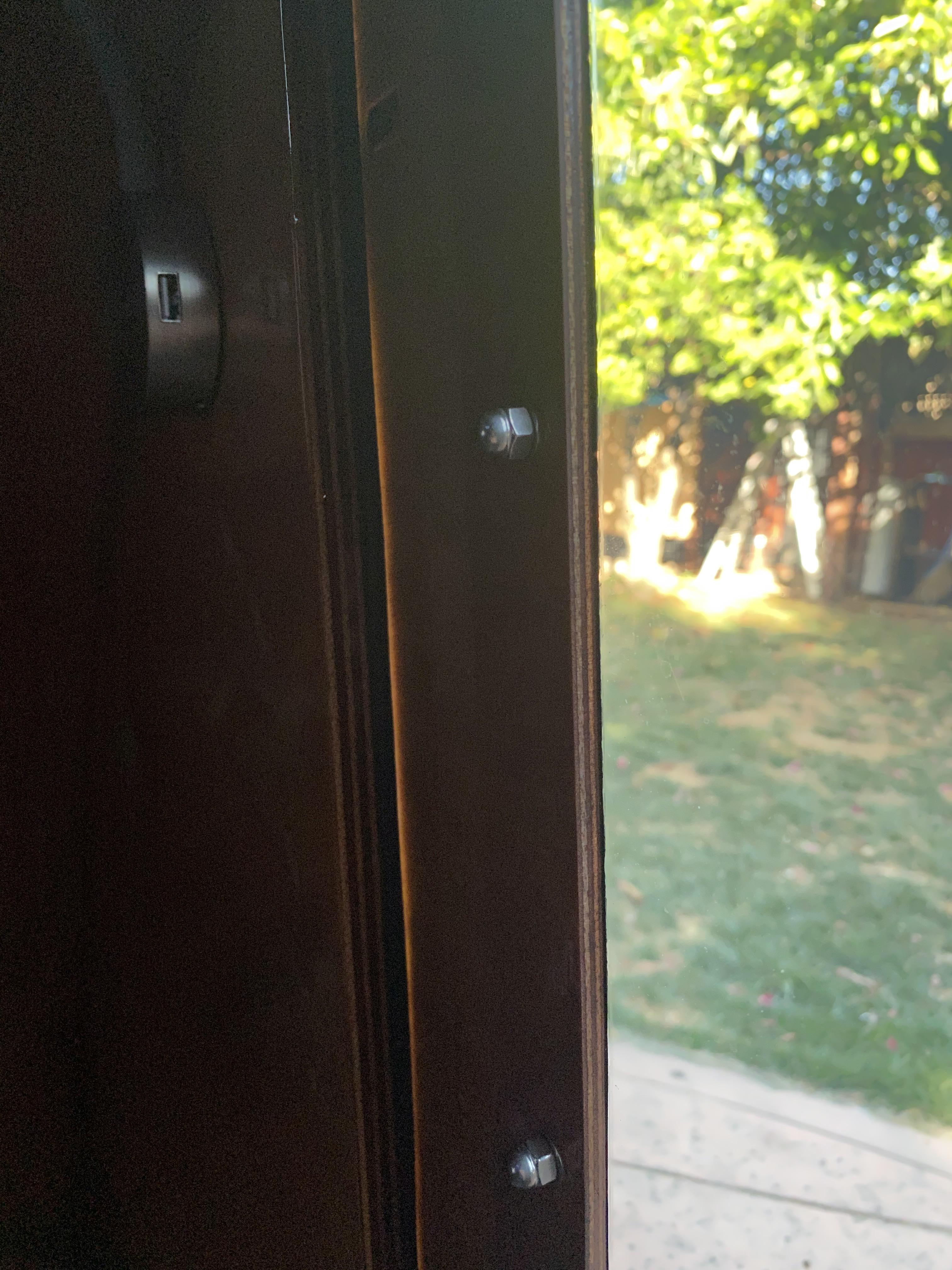

ParticipantOnly the door bows out. The level against the exterior of the trailer is flat against the surface.

canadianhoser

Participant

canadianhoser

ParticipantI was not a fan of the weatherstripping provided in the kit, so I ordered and installed D-shaped weatherstripping which filled in the channel on the chassis itself, making for a much cleaner looking installation. Only one door has this issue, with the other one having a good seal and no leakage.

canadianhoser

Participant

canadianhoser

Participant

canadianhoser

Participantglmcranger, would it be possible to send me a picture of your wiring diagram directly? The version shown here isn’t clear when I expand it. It could be sent to REMOVEwhein1@yahoo.comREMOVE

canadianhoser

ParticipantNot bad. Not enough epoxy runout on the floor.

canadianhoser

ParticipantI’m building mine from a kit, but you could build a simple flattening jig for your router and essentially flatten your ramp. The jig is basically a U-shaped frame that your router sits/slides on. Stack the two pieces you want to scarf together with a suitable offset (ie 4″between ends), and run the router jig across the ramp. Make sure the pieces and the jig are well secured and any runout at the end cuts into a sacrificial board. I hope this is enough info for you to draw upon.

canadianhoser

ParticipantI’ve put 4 coats on the exterior so far and have probably used a quart in the process. I bought 4 quarts and had about 1/2 from a previous project total to use up for the interior and exterior. I just opened up my 3rd quart and have the ICC and tongue-box to complete.

canadianhoser

ParticipantThanks. Does your cam latch against the galley lip or did you build up something to latch against? Any issues of wear with the latch against the surface? I’m thinking of using the galley lip, but adding a metal strike plate at the wear point to eliminate any potential damage.

canadianhoser

ParticipantI’m nearly done with the main construction on my teardrop and I’m getting close to pulling the trigger on my electrical components. I’m going to go with a 100 AH Li-ION battery as the main power source, but still need to determine whether I’m going to install it in the ICC instead of in the galley, and just use the galley space for the rest of my electrical components. Along with shore power, I’m going to get a 100 W portable solar panel and relevant components for charging off grid. I’m going with this so that I can locate the panel in the sunlight but keep the camper out of the mid-day sun. Does anyone care to share the electrical components they are using and any gotcha’s they learned along the way?

canadianhoser

ParticipantSearching online, I found that using a razor blade as a scraper to bring down epoxy/varnish runs is very effective. I can confirm this. Just hold the blade slightly less then perpendicular to the surface you’re scraping, Use this method to break down the high spots, then follow up with your sander to make it all flush.

canadianhoser

ParticipantCan you share where you got your cam locks for the galley hatch?

canadianhoser

ParticipantThanks. I’ve been hitting the bumps with a razor blade as I’ve been working on other areas, and will also go over with the random-orbital sander and possibly some fairing boards before I start any varnish. I’m about 200 pages in on the manual, just completing the doors. I’ve been jumping around a bit, but will be putting a truck bed coating on the bottom this weekend before I flip it back over.

canadianhoser

Participant

The gutter ended up hiding a lot of it, but I added a trim strip to cover the rest and thought it turned out well.

-

AuthorPosts