Forum Replies Created

-

AuthorPosts

-

western_flyer

ParticipantI taped all edges of the galley flat – top and bottom, including the bulkhead/flat on both the cabin and galley sides.

western_flyer

ParticipantYou could situate mushroom vents over the offending area. I put my front vents on panels 3 & 4 because I added knobs to be able to open and close the vents from the inside. The knobs stick out a couple of inches when closed and I would hit my head on them if I mounted them per the manual. They seal just fine, no leaks. Another possibility would be use one the decorative “onlays” that CLC offers. Maybe they would give you a discount for the less than perfect panel.

western_flyer

ParticipantAndrew, this is a work in progress. I took it on the road last weekend for the first time literally an hour after attaching the last fastener. It works pretty well but needs some (quite a few) changes. The plan is to enclose the back and sides and maybe add some sort of screen room/dining space.

Yes I lock the struts open with 1 inch diameter sections of aluminum tubing. I want something to easy and quick to set up not needing poles, guylines and stakes.

As a side not I found the 20 lb OME struts were not up to the winter chill of the northwest. I switch them out for 30 lb struts but they are not strong enough to support the cantilever weight of the canopy.

When I get it tweaked enough I’ll post some pics and descriptions.

western_flyer

ParticipantI fashioned some black netting mesh and Dot fasteners, which seem to hold everything in place.

The SS spice tins to the left are held in place with magnets and purchased from Amazon. (Be sure and read the reviews as some have much better magnets than other offering.)

The magnetic trays are attached to the surface with sticky-back Velcro.

The magnetic trays are attached to the surface with sticky-back Velcro.The side counter to the right and a roll up camp table will soon be held in place with nylon straps and footman loops on the galley flat while transporting.

western_flyer

ParticipantI used the Northern Tool aluminum trailer. I swapped out the OME bias ply tires for radials of the same size (12″). I put one of the OME tires on a new rim for a spare. The bearings seam to be oversize for the loads the teardrop creating, and the 12″ tire more than big enough to handle highway travel and some off road conditions. Nonetheless I purchased two complete replacement bearing sets from NT just to be prepared. It’s a guess on my part but I plan to check and repack the bearings every 10,000 miles initially.

As a customizing note. I didn’t cut the trailer frame down and placed the TD flush with the trailer rear. I did move the axle/spring mounting beam aft to 20 inch from the end of the trailer in order for the doors to clear the fenders. After loading up the tongue box and TD, the tongue load weighed in at about 60 lbs, just about right.

western_flyer

ParticipantI’m in Portland OR but not available until early August.

western_flyer

ParticipantI love you design. I’ve already installed Kedar rail to the TD both to weather proof the galley and put some sort of eves over the doors. https://www.kedersolutions.com/product-category/keder-rail/pvc-rail/

Your idea of putting the dinning area and galley under one shelter makes for a very friendly setting. I would want to extend it to the ground with some screen windows and a zipper door to make life pleasant in buggy areas. I’m a couple of months away from putting needle and tread to fabric but will post my efforts when available.

WF

western_flyer

ParticipantThe 1 inch screws were too short for me also. I used 1 1/2 inch brass screws and used a hacksaw to trimmed them to the right length. I used brass here and in some other areas because it is easy to cut to size and more than strong enough for many situations on the TD. Brass, while not totally corrosion proof, will not rust. The bulkhead screws pass into to the cabin shelf so there is no problem with the length of these.

western_flyer

ParticipantCheck E-Trailer out for higher speed 8″ tires.

https://www.etrailer.com/dept-pg-Tires_and_Wheels-sf-Tire_Only-pc-8_Inch.aspx

western_flyer

ParticipantI’ve used those breaker extension cords in outdoor work situations extensively. They work very well. The one I used had the GFIC built in along with the breaker. It was 15 amp. You might have to go to an electrical supply house to find a 20 amp version.

western_flyer

ParticipantI used a Blue Seas 20 amp marine breaker. More expensive than a house breaker from Home Depot but much more practical and pretty easy to install. I installed it in the “electrical box” area between the cabin and galley. The cabin side has the breaker and a 20 amp GFIC receptacle tucked into an outdoor PVC double gang box with a twin receptacle heavy duty nylon “unbreakable” cover plate. For the breaker I drilled a dummy insert to fit the breaker toggle switch and screw holes. I glued a single gang box to the back of the double, which fit almost perfectly with the face panel on the galley side. I used marine tinned 12 gauge wire throughout.

Do you need a breaker at all? I’ve spent way too many hours viewing how-to RV videos on You Tube. One thing I’ve taken away is the RV park hookups can be wild cards. Some parks may not have 20 amp service and you might have to “dog bone” to a 30 amp outlet and would definitely want some 20 amp protection. Another video showed an example of old 20 amp breakers that didn’t function properly. For $20 bucks an onboard breaker can bring peace of mind.

https://www.bluesea.com/products/category/14/29/Circuit_Breakers/A-Series

western_flyer

Participant While I am sure the provided hinge bolts are more than strong enough for the job, I wanted more bearing surface to reduce wear over time. I went with ¼ inch bolts inserted through nylon bearing sleeves. I drilled a slightly oversize holes, epoxied them, redrilled and pressed in the bearing sleeves. It operates very smoothly. The sleeves are cheap and easily replace when the time comes. Of course one could just get sleeves the size of the supplied hinge bolts.

While I am sure the provided hinge bolts are more than strong enough for the job, I wanted more bearing surface to reduce wear over time. I went with ¼ inch bolts inserted through nylon bearing sleeves. I drilled a slightly oversize holes, epoxied them, redrilled and pressed in the bearing sleeves. It operates very smoothly. The sleeves are cheap and easily replace when the time comes. Of course one could just get sleeves the size of the supplied hinge bolts.

western_flyer

Participant The Waterlust folks are professional film maker with high energy demands. I would think few of us commoners would need anything close to the size and complexity of their electrical system. I’m pretty much on the simple and smallish end of the scale, centered around a 150 watt lithium energy bank, which comes with all the complexity built into the unit. For more power there are 400 watt+ units available.

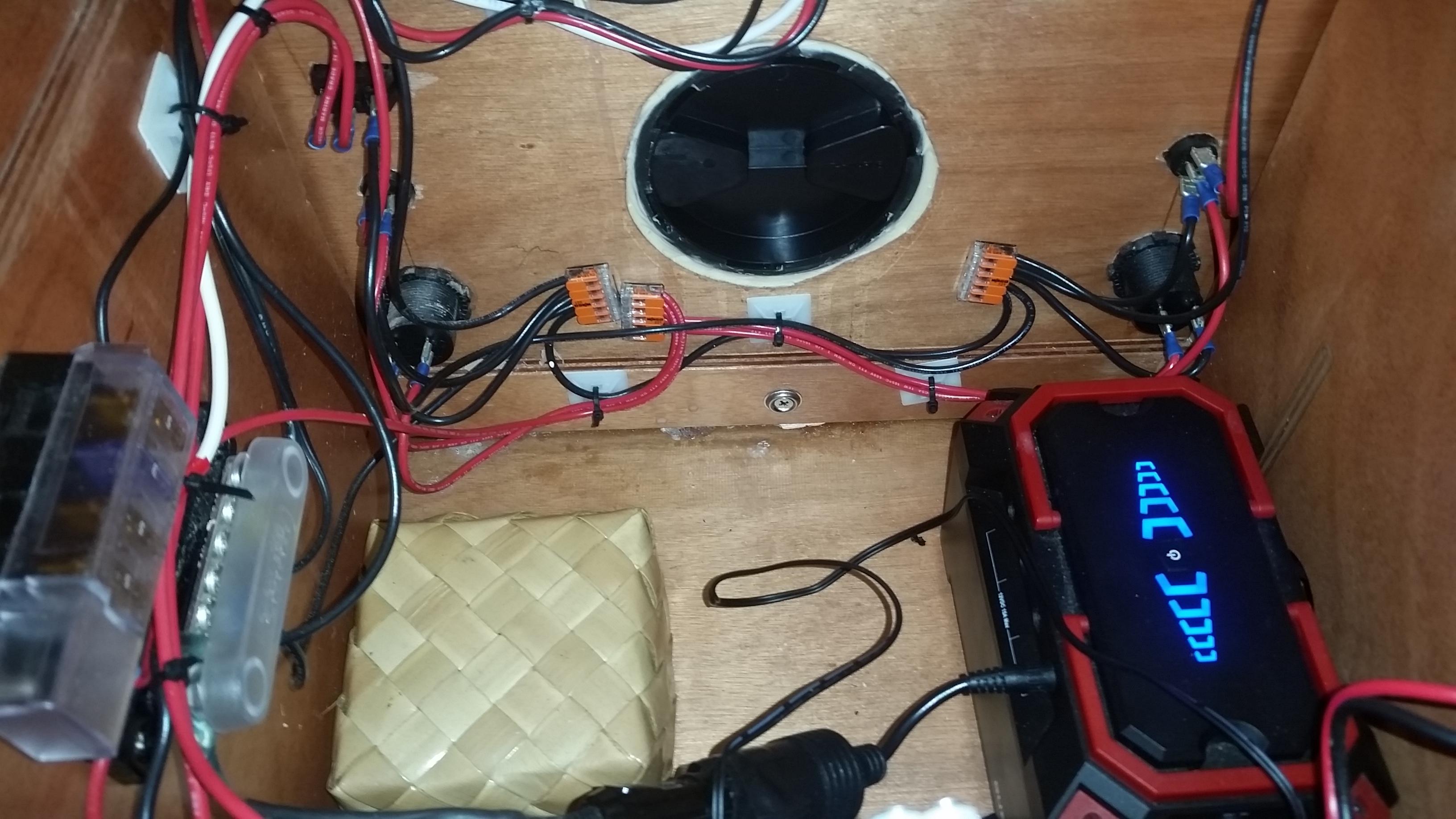

The Waterlust folks are professional film maker with high energy demands. I would think few of us commoners would need anything close to the size and complexity of their electrical system. I’m pretty much on the simple and smallish end of the scale, centered around a 150 watt lithium energy bank, which comes with all the complexity built into the unit. For more power there are 400 watt+ units available.For shore power, 120 VAC, I have a 20 amp marine circuit breaker and a duplex receptacle with GFIC in the cabin and a second receptacle in the chuck-wagon/galley.

I put in a single 12 VDC LED light overhead in both sections and 12 VDC “porch lights” near the doors. There is a scattering of 12 volt receptacles (cigarette lighter sockets) mostly to run USB devices. And a 12 VDC marine cabin fan hardwired to the distribution bars. I have a tiny 200 watt 120 VAC space heater that will only be used with shore power. EDIT And one additional component a twelve volt overhead exhaust fan.

One book I can recommend on 12 volt wiring is “The 12 Volt Bible for Boats”. My copy is 2003 and is weak on lithium batteries which I find to be much lighter, more powerful pound for pound and longer lasting than the lead acid AGM batteries. I used mostly marine electrical wire. If you’re near a West Marine store I found them very knowledgeable and helpful on 12 volt.

There is no wired sound system. Phones, tablets and perhaps a shortwave radio all connected wirelessly via Bluetooth and hotspot Wi-Fi and charge via USB. I’m far from an electric or electronic guru but some of the manuals electrical suggestions seem somewhat last century.

https://www.amazon.com/Portable-Station-Generator-Flashlights-Emergency/dp/B076PR4TBZ

-

This reply was modified 7 years ago by

western_flyer.

-

This reply was modified 7 years ago by

western_flyer.

December 3, 2018 at 2:43 am in reply to: Beautiful and secure doors for the building's entrance #2309western_flyer

ParticipantSPAM

western_flyer

ParticipantI used a hot air gun. I think a blow dryer would do the trick. Just hold the end of the wire with pliers and give a gentle tug while applying heat and wait until the wire starts to budge. The copper wire only took a few seconds to loosen. I used steel wire in a couple of places where the copper kept breaking and it took quite a bit more time and heat.

-

This reply was modified 7 years ago by

-

AuthorPosts