Welcome to TeardropForum.com › Forums › Teardrop Builders’ Forum › Rough plywood

- This topic has 9 replies, 5 voices, and was last updated 6 years, 9 months ago by

derek0.

-

AuthorPosts

-

September 13, 2016 at 11:57 am #165

derek0

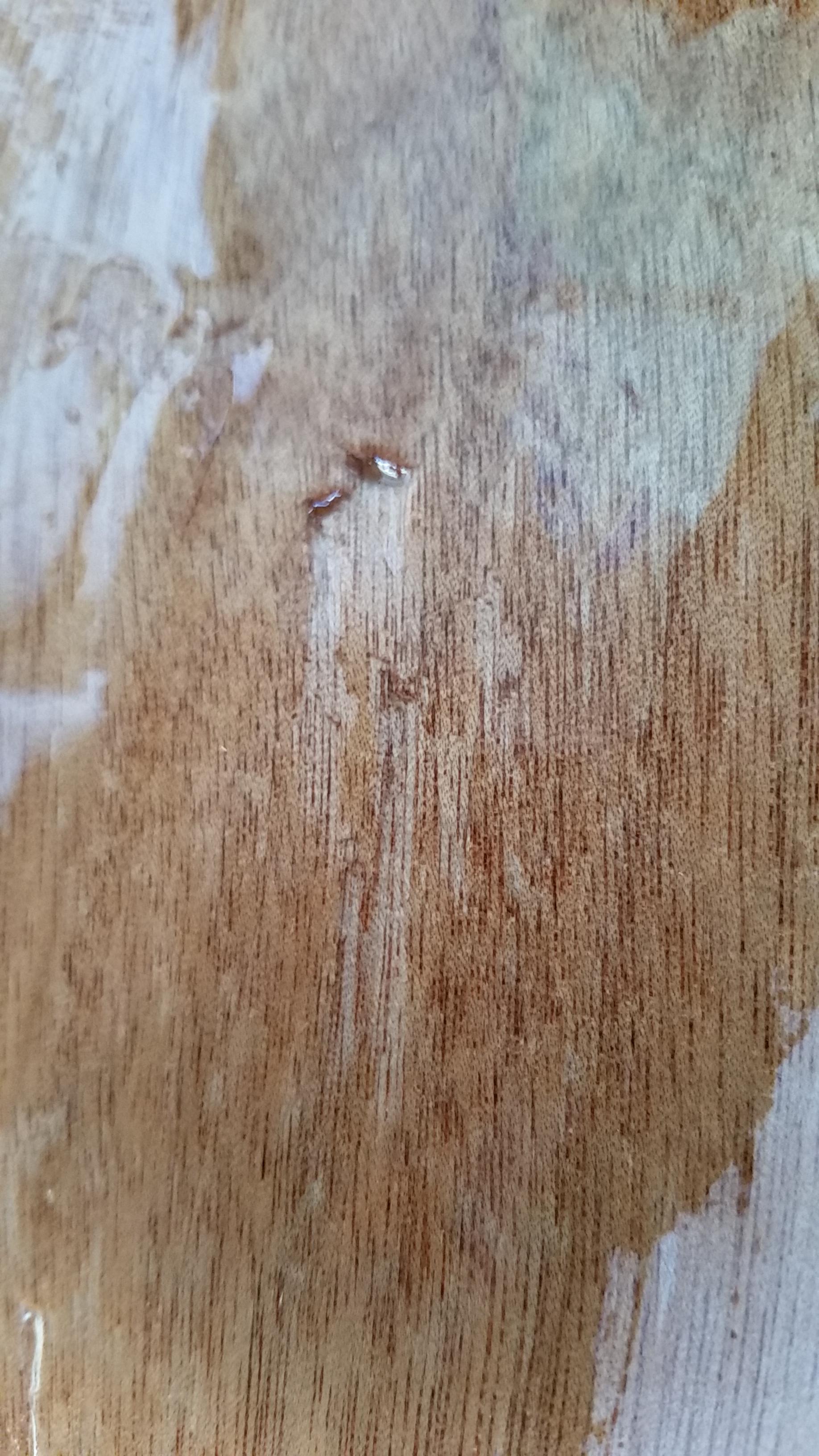

ParticipantI have just started sanding the camper, pre-fiberglass, and I have encountered some serious problems with the exterior surface of the plywood. I have many rather large areas of abraded, rough wood that are not sandable. Initially I though I could smooth them out with the random orbital sander but that tore off small chunks of the outermost veneer leaving me with TWO problems: large areas of unsandable wood AND many small chips in the surface in a few spots. So, what to do?

I have tried to fill the chipped-out plywood with unthickened epoxy (several layers) but it isn’t really filling in. I am inclined to keep trying this, however, and just add more coats. My proactive approach was to paint over the rough wood with a layer or two of epoxy to get a sandable surface, and this seems to work (preventing the tear-out) although it’s going to be visually less than desirable when finished, leaving a big area of ugliness visible in the finish.

Has anyone else encountered this issue? I would greatly appreciate any suggestions anyone may offer.

Thanks for the help!

September 14, 2016 at 12:26 pm #166John C. Harris

KeymasterAny chance you could post or email me a photo?

September 14, 2016 at 8:52 pm #167derek0

Participant September 14, 2016 at 9:01 pm #169

September 14, 2016 at 9:01 pm #169derek0

ParticipantThe previous picture shows one of the bad spots after sanding with 120, and I am planning to gingerly sand with 220 and call it “good”, unless consensus says I should continue with the 120. I would likely sound through the outer veneer to get 100% smooth.

The above picture shows one of the larger tearouts (about 5mm square) after a couple coats of epoxy. My plan was to get it to fill in a bit better then sand of nearly all the epoxy on the smooth wood, hopefully leaving a nicely filled chips/divots. I’m not sure how this is going to look under the glass.

September 21, 2016 at 6:09 pm #171friz

ParticipantI am curious to know how this turned out.

September 21, 2016 at 11:57 pm #172Thomd

ParticipantIf you want a clear finish, that may be a problem. Clear finish looks OK in some cases, but is a huge maintenance headache, if that makes it any better. Most people won’t see the top panel all that well, at least painting that would help. Either paint or bright, I would be inclined to bog it with epoxy and wood flour: you wet coat the bad areas but let it sink in, then bog it, and immediately glass it. All one step so that you don’t have to sand or anything. if you have only one area that is damaged, this is pretty easy. Takes an experienced hand if the blotches are everywhere and you end up having to do a wet layup, or a combo wet dry layup.If on another occasion you find short grain like this in a panel, pre-finish it with epoxy, or glass, that way it won’t lift up when you torture. If this was a kit panel it should have been replaced.

Another option with clear is to bog the rough patches with epoxy thickened with cab, that will allow you to fill with a material that is somewhat transparent, without building up the highs as well as the lows. But a cab bog is really hard to sand.

January 26, 2017 at 8:43 am #485ButchFNJ

ParticipantHello, New to the forum and not as experienced as some of you with this kind of work. Wondering what wet coating, bogging and cab are. Also how did it turn out and what did John Harris say after he saw the pictures??

Looking forward to the helpful hints and tips from this forum! I have been working on my camper for a few months in between work but have suspended operations as it’s pretty cold here in NJ at the moment and I don’t want to screw up the first big glass project.

October 25, 2017 at 4:53 pm #1419ButchFNJ

ParticipantSo I have been a holding pattern on my build for the last 9 months:( But I’m back at it and have been perusing the forum.Great info from all contributors! However when this post came up back then I had asked what JH at CLC had responded. And also about some of the suggested fixes from other contributors. Wet coating, bogging and cab? Not sure what these processes are.

Was there every a response from CLC as to what derekO should do?

October 26, 2017 at 11:17 am #1420friz

ParticipantI had an area that looked similar. I carefully sanded that area by hand in a direction that would not chip out the veneer, then pushed forward as normal. I couldn’t even tell you where it was now.

October 26, 2017 at 3:44 pm #1421derek0

ParticipantHi ButchFNJ,

I’m still working on the project, if you can believe it! The weather here tends to go from too hot to too cold in a flash, limiting the time I am willing to spend in the garage. Anyway, I am done with all assembly except for fixing the fit of the doors… Now I just need some good painting weather. And yes, I will not be going natural with the trailer except the interior, although I doubt the imperfectness of the wood would detract from appearances.

It turns out that the chipped out bits of plywood are hardly visible under the epoxy. I never got feedback to my original post other than in this forum so I can’t offer much advise except to be very careful of any unfinished wood before it gets some epoxy and/or fiberglass on it. Unfortunately these problem areas can be worsened (and maybe caused) by wiping down the sanded wood surface with a rag dampened with alcohol.

Good luck with the build and have fun!

-

AuthorPosts

- You must be logged in to reply to this topic.