Welcome to TeardropForum.com › Forums › Teardrop Builders’ Forum › Color Scheme Opinions? › Reply To: Color Scheme Opinions?

@abrightwell, if you had bubbling beneath the fiberglass (i.e. the fiberglass looks like it bulged out) due to temperature variation, it sounds like you are describing a bad mix ratio of resin/hardener, not outgassing (uncured epoxy expands according to my conversations with CLC). If that is the case, you might be able to salvage it and not have to paint at all.

We had similar bubbles during our build along both #1 panels about two feet down from the fan bezel, where the curve really starts rounding toward the bottom. We didn’t notice them until a few weeks after we epoxied when the temperature changed dramatically. We thought we would have to paint over or cover them with a stripe.

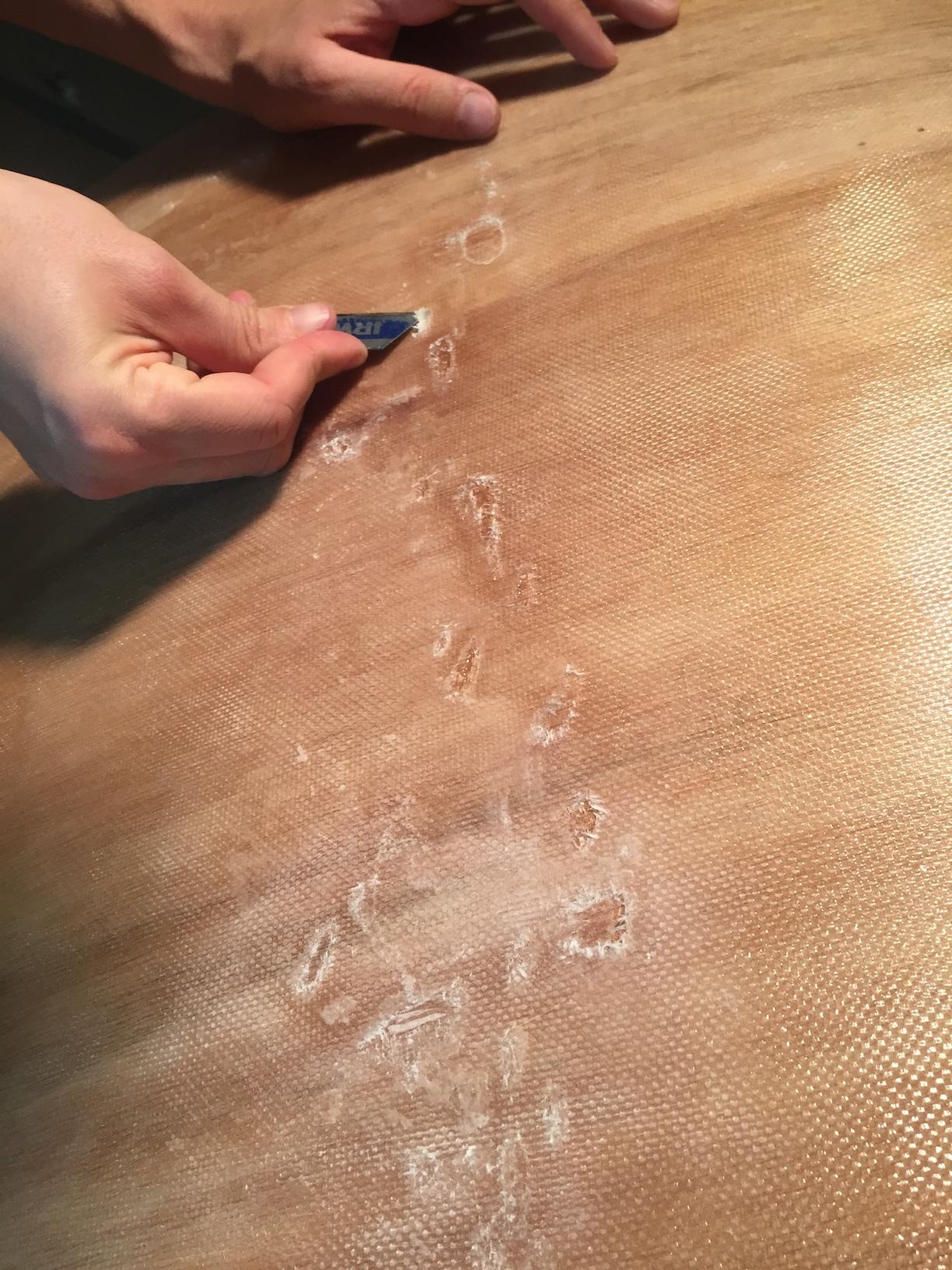

Our solution was to surgically remove the fiberglass bubbles down to the wood with a razorblade (VERY carefully to protect the wood), and then clean out the soft uncured resin with denatured alcohol. We then patched the holes with two layers of fiberglass (one the size of the hole, the next a square patch covering the hole), both soaked with epoxy. Once dried, the edges have to be smoothed out into the surrounding ‘glass. The whole process was time consuming, but the end product looks natural and we can’t tell there were ever any bubbles (but it will look patchy until the varnish blends everything). Pics below:

-

This reply was modified 6 years, 6 months ago by

apkley.