Forum Replies Created

-

AuthorPosts

-

May 23, 2024 at 10:29 am in reply to: Epoxy rollers falling apart when rolling epoxy resin. #22138454

rlheestand

ParticipantThanks! I think that the epoxy heating up in the rollers was contributing to the foam layer delaminating from the roller. I am in Texas and am trying to cope with higher temperatures and shorter working times. I find that if I pour the epoxy out on the parts (instead of working out of a tray) that I can get longer working times.

rlheestand

ParticipantSeems to be working now.

rlheestand

ParticipantI am receiving “This forum is empty.” There are no topics. Do others receive this?

April 11, 2018 at 4:54 pm in reply to: Joint between galley Flat and bulkhead failed when plywood delaminated. #1765rlheestand

ParticipantAdded one layer of 3 inch fiberglass tape to the galley side of the galley flat/bulkhead joint. I have painted two layers of fiberglass over the tape and will sand it prior to varnishing to make it a little less visible.

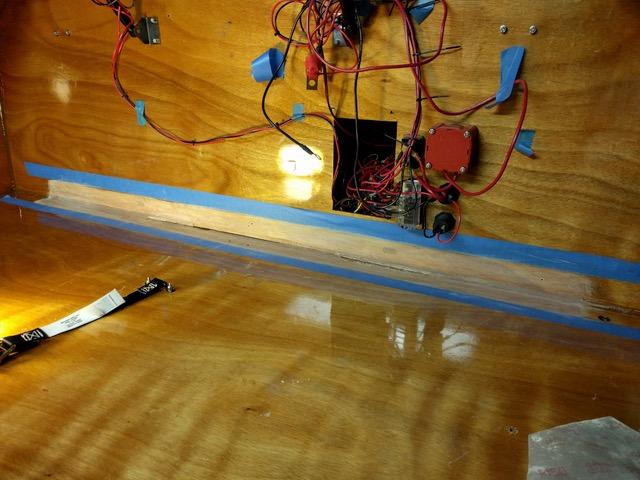

Here is the interior. I have added two layers of fiberglass tape (one 4 inch wide strip and one 3 inch wide strips). This should be plenty strong.

Next, sand, varnish and reinstall the galley.

April 11, 2018 at 4:48 pm in reply to: Joint between galley Flat and bulkhead failed when plywood delaminated. #1764rlheestand

ParticipantI visited with CLC boats last weekend at the Port Aransas wooden boat festival to look over the prototype teardrop camper and pick up any tips on their construction. I saw that there was slight delimitation of the galley flat at the joint with the bulkhead (about a fingernail width crack). They had added a pair of metal braces (very nice looking) to reinforce the joint. Got a picture of the teardrop, but didn’t get a closeup of their galley flat / bulkhead joint.

March 16, 2018 at 4:35 pm in reply to: Joint between galley Flat and bulkhead failed when plywood delaminated. #1721

March 16, 2018 at 4:35 pm in reply to: Joint between galley Flat and bulkhead failed when plywood delaminated. #1721rlheestand

ParticipantPrepared the galley by sanding off the varnish with 150 grit sandpaper and removing shards of plywood veneer and old epoxy fillet. In each case the epoxy had pulled the veneer off the plywood sheet. I added a new fillet (slightly broader) and immediately added a 3 inch fiberglass tape between the galley flat and the bulkhead. I am waiting for CLC to send a strip of 4 inch fiberglass tape which I will apply to the joint from within the cabin.

Prepared for tape

Preparation closeup

Tape added

-

This reply was modified 6 years, 4 months ago by

rlheestand.

March 14, 2018 at 2:11 pm in reply to: Joint between galley Flat and bulkhead failed when plywood delaminated. #1713rlheestand

ParticipantYes, I had secured the battery with a battery strap within a battery box. I am next going make a battery tie down strap using a ratcheting strap (constructed by cutting down a longer tie down strap from home depot) so I can feel more secure about the strap remaining tight and to make it easy to check and retighten.

I found on a fiberglass supply sight that the strength of the tape is about 100 lbs / inch in the direction of the fibers, so I suspect that that would be plenty strong enough for a strip running inside the cabin. I am also considering adding a strip in the galley (belt and suspenders).

If the problem recurs I will consider the lithium route.

March 12, 2018 at 3:46 pm in reply to: Joint between galley Flat and bulkhead failed when plywood delaminated. #1705rlheestand

ParticipantJust spoke with CLC and they were very helpful. The recommendation now is to reinforce that joint with a strip of fiberglass during building. They are supplying a 4″ strip which I will use to reinforce the joint from within the cabin.

-

This reply was modified 6 years, 4 months ago by

-

AuthorPosts