Forum Replies Created

-

AuthorPosts

-

madebymike60

Participant5) Finally, clean up is pretty easy. You can use a utility knife to score the butyl right at the edge of the gasket. Be careful with this, you don’t want to cut through your wood finish. The butyl cuts easily and you don’t need to cut all the way through it for it to peel away. It helps to use a small amount of extra to dab at and pull the squeeze-out off. You might find that a day or so later you need to do that again because the butyl will continue to ooze out. That makes it sound like it’s messy but it’s not. When it’s cleaned up, you’ll have a neat installation. If you look up ‘butyl vs silicone’, you’ll see others’ opinions about using it on RV’s and boats but it seems like it will serve this purpose well.

madebymike60

Participant4) When you are ready to install the gasket, start at the bottom back (like the directions show) and work your way around, squeezing the gasket onto and tightly over the gutter. It takes some force to get the gasket on well and at times I used a rubber mallet to persuade it to go all the way on. Make sure at every change of direction, no matter how small a change, that you squeeze the gasket into the ‘corner’ really well before moving on. I didn’t one time and had to pull some of the gasket off, back up and try again, something that would be very difficult (and messy) if I had used silicone. When you’re done, you should have a pretty consistent amount of squeeze out all the way around.

madebymike60

Participant3) After a little while, you’ll have a continuous ‘bead’ of the soft material all the way around the gutter. There’s no need to hurry and get the gasket installed because the butyl won’t drip or dry out.

madebymike60

Participant2) Then just stick the butyl tape pieces to the edge of the gutter, trying to center it as best you can.

madebymike60

ParticipantI appreciate the feedback. I don’t think the conventional method will fail either. If it didn’t work well, there would be posts about it here and the only ones are about the difficulty of lining up the holes, etc. I also don’t think my method will fail and if I had the slightest notion that it might, I wouldn’t have done it on my camper and certainly wouldn’t have put the idea in the forum.

Bolt heads in the floor was a minor reason for thinking of a different method and only occurred to me after the fact. The two biggest reasons were the possible water issue and having to flip the camper twice at this point. I’m working alone and while I could get help to do the flips, I was trying to avoid it. Also, with the drill/fill method and plenty of sealant, it’s very unlikely water would be a problem at the holes. (My method has zero chance though.) It’s just that they are in a place that could go unnoticed for a while and I read several people sharing (on a tiny trailers forum) how the floor is about the worst place to have water damage.

Finally, I like to problem solve and try to come up with creative solutions when possible. No one should try my method without understanding that it hasn’t been ‘real world tested’. If a moderator of this forum feels like it is not a good alternative, they should remove the post(s) and I’ll understand. I’ve seen so many good ideas from other builders here and I simply thought I had one more…but maybe not.

madebymike60

ParticipantYou do have to buy the aluminum and shorter bolts (together they were about $16) and maybe a bigger drill bit but benefits include:

1) You’re not putting holes in the bottom of the camper so there’s no chance of water intrusion there

2) You don’t have to remove the camper from the trailer and turn it upside down (to drill the holes)

3) There won’t be any bolt heads in the floor of your camper – I know a mattress would cover them but still…

4) It’s relatively easy to do everything – the hardest part is probably cutting the aluminum but there are ways to make it easier – metal cutting circular saw blade, jigsaw blade or grinder, for example – but if it’s all you’ve got, a hacksaw will work.

Finally, a mechanic’s creeper makes moving around under the trailer easier. Obviously, time will tell how well this method works but from a few simple tests, it seems like it will do the job.

madebymike60

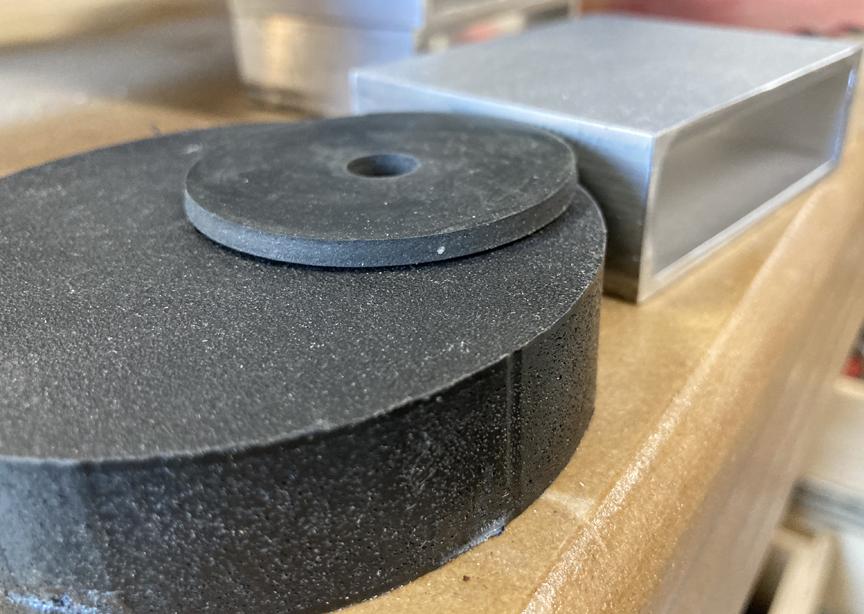

Participant8) Here’s one with the rubber washer in place. The one inch bolt is just long enough to work since the lock nut is on tight but 1 and 1/4 length would also work. Any longer than that and the bolt would probably hit the top of the aluminum tubing.

madebymike60

Participant7) A right angle drill attachment will give you access to the brackets above the trailer axle.

madebymike60

Participant6) To attach the other eight pieces, I used an air shim to raise the camper so there was enough room to put the aluminum pieces in (with epoxy smeared on the top) and add woodworking shims to push them upward against the camper. I did two at a time because of the five minute set time of the epoxy. The air shims were used again later when inserting the rubber dampeners. They can be quite handy.

madebymike60

Participant5) Here’s a little test I tried after about 12 hours of cure time. Only two pieces of the aluminum tubing are epoxied at the back and they are holding the trailer as it comes off the ground. It looks more impressive than it is since that’s only a small fraction of the force it would take to separate the tubing from the trailer (according to the epoxy data sheet).

madebymike60

Participant4) Once the epoxy has set, you’re ready to drill a 3/8″ hole through the bottom of the aluminum tubing and bolt it to the trailer. Once you get through the bottom of the tubing, stop drilling. I used stainless 5/16 – 18 x 1″ hex head bolts and the lock nuts that came with the trailer, plus flat and lock washers. Below is one installed and with the hockey puck spacer removed. Install one at each of the brackets and the camper should stay put. In testing a piece of aluminum epoxied to plain wood, I could not hammer them apart so I’m expecting these to stay together a long time. This picture doesn’t show it but I put a rubber dampener between the bracket and aluminum piece later. I’m not sure if they’re needed since in the camper directions they are used to ‘protect the camper bottom from wear’ and with this method, that shouldn’t happen.

-

This reply was modified 4 years, 2 months ago by

madebymike60.

madebymike60

Participant3) At this stage, you should have something holding your camper a little off the trailer – hockey pucks in my case. I used Loctite brand epoxy because it sets in about five minutes (though the kit epoxy would probably work just fine), and spread some on the sanded side of a piece of the tubing. Slide under your camper and insert the tubing between the camper bottom and one of the brackets attached to the trailer. Mine had just enough space for me to fit the tubing (and not have all the epoxy come off) because of the hockey pucks but you might have to prop or lift a section of the camper up slightly to make room. Also, if your camper bottom is shiny from (kit) epoxy, it should be sanded in that spot for the (aluminum) epoxy to stick better. I had coated the bottom of my camper with U-pol Raptor liner and their tech support said the epoxy should stick well to it. Here is one being wedged tight against the camper bottom until the epoxy sets. The hockey puck spacer is still in place on the right side.

-

This reply was modified 4 years, 2 months ago by

madebymike60.

madebymike60

Participant2) The one inch height is just over the combined height of the ‘hockey puck’ spacer and rubber washer that are shown in the directions so that size is about right. Two inches wide might work but three inches seems good because there’s more room for epoxy and plenty of room to get a wrench and fingers inside to help tighten the nut and bolt.

madebymike60

Participant8) Here’s a final view. The cross piece is an ‘L’ shape and pretty beefy – anywhere from 1/8 to just over 3/8 inches thick. The top of the wood support was rounded and tapered a little to fit nicely. The fan cover can open a little so even with the solar panel in place, the fan can still be used. Overall, I’m very pleased with how the rack looks and it seems like it will work very well.

madebymike60

Participant7) Here’s another look at the (nearly) finished rack. It seems very strong and just needs some epoxy or paint to protect the wood. There’s about an inch of clearance between the top of the rack and the fan cover but it can open a couple of inches with the solar panel in place because the panel has a recess under it (mine does anyway). It did take quite a few hours to figure out and make but I’m retired and have the time. The aluminum cost about $28 and the bolts were only $5 from Amazon so it was very reasonable as far as cost.

-

This reply was modified 4 years, 2 months ago by

-

AuthorPosts